TORONTO, ON / ACCESSWIRE / July 6, 2020 / AEX Gold Inc. (TSXV:AEX) ("AEX" or the "Corporation") is pleased to provide an update on the results of recent test work aimed at assessing the potential to use ore sorting to improve the processed grade of materials at the Nalunaq Gold Project in South Greenland.

Key Highlights:

- AEX has worked with leading provider of sensor-based solutions, TOMRA, to investigate the potential application and efficacy of ore sorting at the Nalunaq Gold Project;

- Ore sorting uses various detectors to identify minerals from waste material, which could be particularly attractive for the Nalunaq Gold Property given the contrast in density and colour of the white and gold bearing mineralized quartz vein and the non-mineralized host rock;

- A 500kg bulk sample of mineralized Main Vein ("MV") material, collected from the historical underground workings, was used for a preliminary performance test at TOMRA's test facility in Wedel, Germany;

- The performance test report confirms that Nalunaq's mineralized material is highly amenable to Ore Sorting Technology;

- Laser sorting technology showed favourable results in the preliminary performance test, with total gold recovery ranging between 90.2% and 99.4% and with mass rejections of waste ranging from 58% - 62% of the incoming feed stream;

- A second test, planned for 2021, will focus on optimizing the detection parameters to increase confidence in gold recovery;

- The Corporation believes that this ore sorting technology, once optimised, could offer a cost-effective processing solution to supplement the Company's existing plans.

Eldur Olafsson, CEO of AEX, stated:

"Ore sorting has the potential to be a cost-effective solution for processing Nalunaq's mineralized material. We are pleased to continue progressing on the development of the Nalunaq project by involving industrial cutting-edge technologies in our development strategies."

Given the positive outcome of the test, AEX will continue refining and progressing its approach to Ore Sorting to consider the potential inclusion of an ore sorter in Nalunaq's process flowsheet.

Background

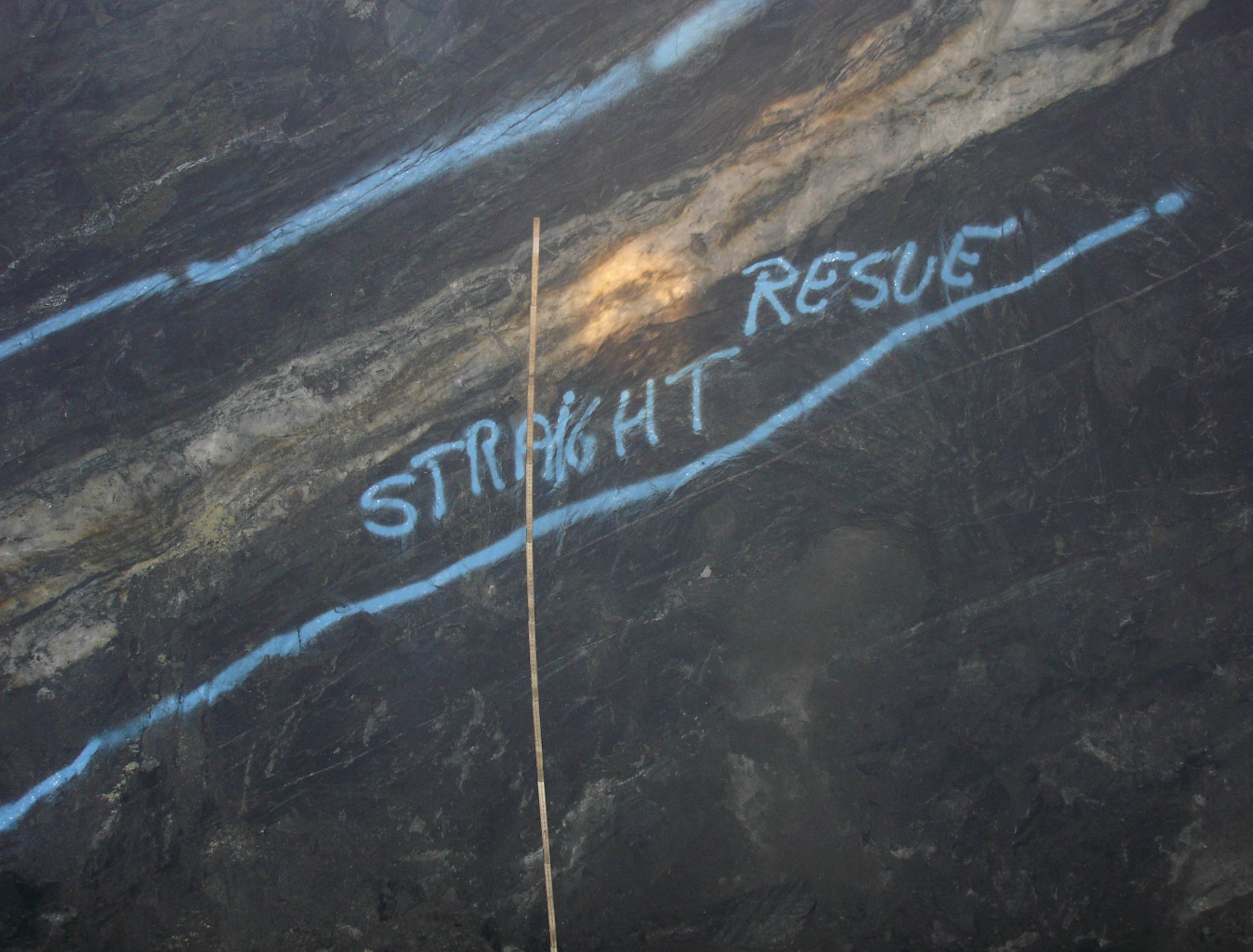

Gold at Nalunaq is mineralised in a quartz vein (MV), which averages 0.7 meters in width and exhibits a typical "nugget effect". Past mining operators have used a combination of selective resue mining and conventional long hole stoping, which resulted in an average true mining width of 1.2 meters. Therefore, the mined material includes a significant quantity of amphibolite host rock (devoid of gold and considered as dilution). It is anticipated that ore sorting could be effective at Nalunaq due to the contrast in density and colour between the high-grade gold-containing quartz veins (white) and host amphibolite (dark grey). See below Figure 1 illustrating the colour difference between MV and the waste host rock:

Figure 1: Typical Face of a Sublevel, illustrating the white mineralised quartz of MV on the dark amphibolite waste

The potential removal of the host rock from mill feed could therefore enable significant upgrading of the mined material, lower processing costs and enable an increase in milling throughput.

Ore sorting technology has been employed in various mineral processing operations for many years and is now used with a variety of commodities including diamonds, tin, tungsten and gold. The ore sorting process has become increasingly efficient with advancements in sensors and in computing technology.

Approximately 500 kg of typical Nalunaq mineralized material was sourced from the 460 level in Target Block. The sample was hand-picked from broken material in the drive. Twenty eight percent of the sample mass was mineralized quartz vein material with the remaining 72% being unmineralized amphibolite and granite. The sample was representative of the relative proportions of different rock types on the 460 level. See Table 2 below which provides more information as to the composition of the sample:

Table 1: Ore Sorting Bulk Sample Description

Bag Containing | Description | Location | Mass (kg) |

Waste | Amphibolite | 460 L W | 43.6 |

Waste | Amphibolite | 460 L W | 44.2 |

Waste | Amphibolite | 460 L W | 36.6 |

Waste | Amphibolite | 460 L W | 40.6 |

Waste | Amphibolite | 460 L W | 42.2 |

Waste | Amphibolite | 460 L W | 38.4 |

Waste | Amphibolite | 460 L W | 39.3 |

Waste | Amphibolite | 460 L W | 39.7 |

Waste | Granite / Aplite | 460 L W | 35.5 |

Ore | Quartz Vein | 460 L W | 36.7 |

Ore | Quartz Vein | 460 L W | 38.0 |

Ore | Quartz Vein | 460 L W | 33.9 |

Ore | Quartz Vein | 460 L W | 31.8 |

Total | 500.4 | ||

Waste | 72% | 360.1 | |

Ore | 28% | 140.3 | |

Tests were operated on two particle size fractions: 20 mm to 40 mm, and 40 mm to 60 mm material (typical particle sizes in crushing circuits and amenable to ore sorting). Throughout testing, the ability to effectively sort mineralised quartz vein was clearly demonstrated and results from the tests were positive. Significant upgrades of gold were achieved in the four tests which were operated (two using the laser sensor and two using the x-ray transmission (XRT) sensor). The results of the tests are illustrated in Table 2 below:

Table 2. Results of the Nalunaq material Ore Sorting Test

Test # | 1 | 2 | 3 | 4 | |

Sensor | Laser | XRT | |||

Size range [mm] | 20-40 | 40-60 | 20-40 | 40-60 | |

Feed | Mass [kg] | 69.3 | 156.0 | 71.0 | 170.0 |

Au [g/t] | 107.9 | 10.3 | 40.4 | 24.3 | |

Waste | Mass [%] | 58.3 | 61.9 | 62.7 | 70.6 |

Au [g/t] | 18.1 | 0.1 | 2.0 | 11.0 | |

Product | Mass [%] | 41.7 | 38.1 | 37.3 | 29.4 |

Au[g/t] | 233.4 | 26.8 | 105.0 | 56.2 | |

Au Recovery [%] | 90.2 | 99.4 | 96.9 | 68.0 | |

Concentration factor | 2.16 | 2.61 | 2.60 | 2.31 | |

Figure 2 below shows an example image of the product and waste streams for test #2 (laser):

Figure 2: Example image showing the product (left) and waste (right) streams from Test #2 (laser)

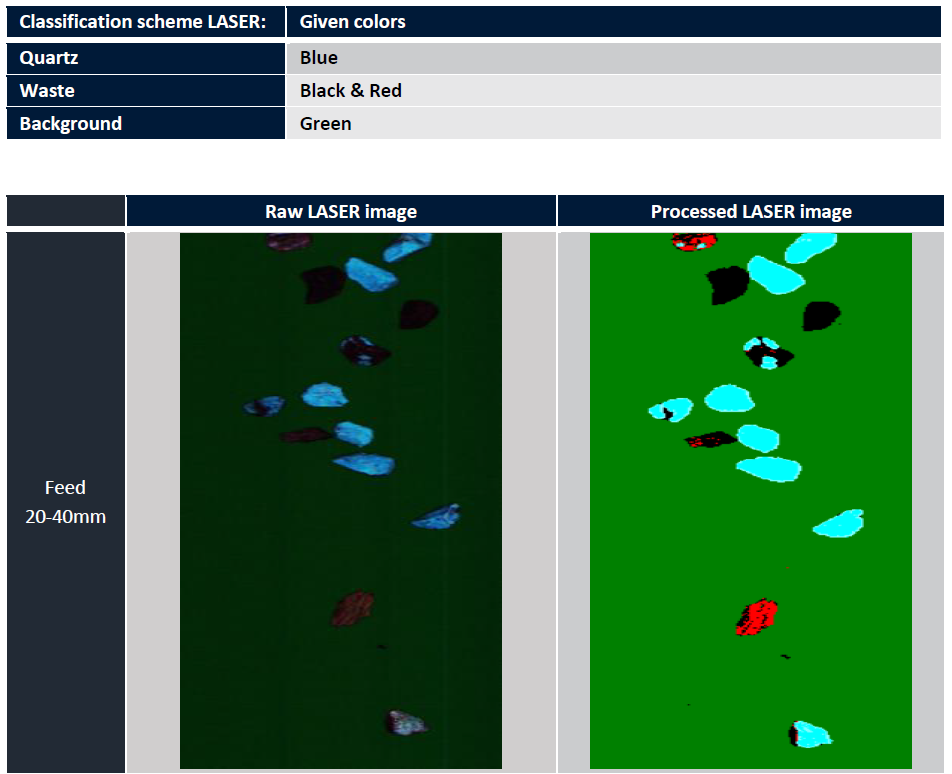

Figure 3 below illustrates examples of the raw and processed particle images using the laser sensor. The images show the sensor's ability to differentiate between quartz and waste rock.

Figure 3: Example images the raw (left) and processed (right) image using the laser sensor (blue indicates quartz, red and black indicates waste, green is background).

The primary objective of the test was to assess the amenability of the Nalunaq mineralised materials to detection by ore sorting technology. AEX recognizes that the test has demonstrated conceptually that ore sorting is potentially highly effective at detecting and separating particles containing quartz and should be further investigated.

The Corporation is currently planning to undertake a second campaign of ore-sorting test work with TOMRA by further investigating a 500-1000kg sample of material of a 10-50mm fraction size. This test, planned for 2021, will be focused on optimizing the detection parameters of the laser and XRT sorters, and therefore gold recovery. The results from the second phase would then be evaluated and a trade-off study on ore sorting would be developed with an experienced third-party consultant.

Qualified Person and QA/QC

The scientific and technical information presented in this press release has been approved by James Purchase, P.Geo. (OGQ 2082), Director of Geology and Resources of G Mining Services Inc. and independent to AEX Gold Inc. for purposes of National Instrument 43-101 - Standards of Disclosure for Mineral Projects ("NI 43-101"). Mr. Purchase is a member of the L'Ordre des Géologues du Québec, and a "qualified person" for purposes of NI 43-101. Mr. Purchase has visited the Nalunaq Project and has verified the results reported in this press release.

Sample preparation and assays were carried out by Wheal Jane Laboratory of Cornwall, England. Gold assays were performed with the M4 screened metallics method, which is a UKAS 17025 accredited method. This involves stage pulverising a 1 kg sample through a 106 µm screen until between 30 g and 50 g of oversize material remain. This entire oversize fraction along with two similar sized duplicate fractions of the undersize are then assayed to extinction in order to determine gold content. The Screened Metallics protocol reduces the likelihood of factors such as the nugget effect influencing the results of the head assay.

For the purpose of the Performance Test, 489kg of the AEX Gold material were received. For sizing 8mm mesh, a 20mm mesh, a 40mm bar-sizer and a 60mm bar-sizer were used. The received samples contained a significant amount of oversized material, which has been crushed manually after sizing to -60mm and added to the other fractions. For test work purpose the fractions 20-40mm and 40-60mm were used. Material 20-40mm as well as +40-60mm has been divided each into two equivalent samples with aim to test two different methodologies: LASER and XRT for each fraction. Material proposed for the LASER, has been washed before the sorting, since this technique requires a clean surface.

Contact Information

George Fowlie, Director and CFO

1-416-587-9801

gf@aexgold.com

Eldur Olafsson, Director and CEO

+354 665 2003

eo@aexgold.com

Camarco (Financial PR)

Gordon Poole / Nick Hennis

+44 (0) 20 3757 4980

About AEX

AEX's principal business objectives are the identification, acquisition, exploration and development of gold properties in Greenland. The Corporation's principal asset is a 100% interest in the Nalunaq Project, an advanced exploration stage property with an exploitation license including the previously operating Nalunaq gold mine. AEX is incorporated under the Canada Business Corporations Act and wholly owns Nalunaq A/S, incorporated under the Greenland Public Companies Act.

Forward-Looking Information

This press release contains forward-looking information within the meaning of applicable securities legislation, which reflects the Corporation's current expectations regarding future events and the future growth of the Corporation's business. In this press release there is forward-looking information based on a number of assumptions and subject to a number of risks and uncertainties, many of which are beyond the Corporation's control, that could cause actual results and events to differ materially from those that are disclosed in or implied by such forward-looking information. Such risks and uncertainties include, but are not limited to the factors discussed under "Risk Factors" in the Final Prospectus available under the Corporation's profile on SEDAR at www.sedar.com. Any forward-looking information included in this press release is based only on information currently available to the Corporation and speaks only as of the date on which it is made. Except as required by applicable securities laws, the Corporation assumes no obligation to update or revise any forward-looking information to reflect new circumstances or events. No securities regulatory authority has either approved or disapproved of the contents of this press release. Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

SOURCE: AEX Gold Inc.

View source version on accesswire.com:

https://www.accesswire.com/596212/Ore-Sorting-Increases-Grade-of-a-Bulk-Sample-by-up-to-161-at-AEXs-Nalunaq-Project