TORONTO, ON / ACCESSWIRE / July 10, 2020 / AEX Gold Inc. (TSXV:AEX) ("AEX" or the "Corporation") is pleased to provide an update on the results of a recent metallurgical test work program which was aimed at confirming the historical gravity gold recovery results of the mineralized materials from the Nalunaq Gold Project, in South Greenland.

Key Highlights:

- The AEX 2020 Gravity Recoverable Gold (GRG) test work was conducted at SGS Canada Inc. facility in Lakefield, Ontario, Canada;

- 2020 test result shows 90% GRG using the standard test method1;

- Historical GRG test work yielded results of up to 89% (Kvaerner, 2002)2;

- 2020 Test work reproduced and marginally outperformed the historically high GRG results from the past metallurgical investigations;

- The Nalunaq Gold Project's mineralized material is highly amenable to gold recovery using gravity recovery methods;

- Gravity gold recovery is a cornerstone element of the processing methods at Nalunaq.

Eldur Olafsson, CEO of AEX, stated

"Gravity gold recovery is impressively high and is a cornerstone for processing at Nalunaq. The gravity amenability of Nalunaq's mineralized material was recognized first-hand early in the history of the project and will be leveraged in the future development of the asset.'

Background

Gold at Nalunaq is mineralised in a quartz vein hosted in an amphibolite-granite sequence and is classified as a narrow-vein orogenic lode-gold type system. The vein is generally less than 1 meter in thickness and is dominated by coarse, often visible gold and a nuggety grade distribution. Figure 1 shows an example of a high-grade sample from Nalunaq's Main Vein.

Figure 1: Example image showing a high-grade gold-quartz vein sample from the Nalunaq Main Vein containing coarse gold (Nalunaq 43-101 report, 2016). The picture is of selected material and is not representative of the mineralization hosted on the property.

The GRG test was developed to characterize gold bearing material's amenability to gold recovery using gravity techniques. An Extended Gravity Recoverable Gold (EGRG) test was also developed which requires a smaller sample and which simplifies the procedure. The test procedures have been the industry standard for over two decades. The test involves gold recovery in three stages to determine the GRG as it is liberated at finer grinding sizes. Exceptional testing results have been obtained historically using samples of Nalunaq's mineralized material.

Two samples (Level 350 Composite and Level 450 Level Composite) were tested in 2001 at McGill University where the GRG test procedure was developed and yielded GRG of 85% and 89%, respectively (Kvaerner, 2002). GRG in the samples reported mostly at a coarse size, and was predominantly liberated or near liberated. Recommendations made as a result of the test work for the full-scale plant included the use of vigorous gravity recovery in the process flowsheet.

Historical processing (2003-2006) of Nalunaq mineralized material at an industrial-scale was undertaken at the El Valle plant in Spain, which included gravity recovery. Results from the processing campaigns revealed an average gold recovery by gravity of 65%. It should be noted that, although the gravity recovery at El Valle was high, gravity circuit at the El Valle plant was not designed specifically for Nalunaq's mineralized materials. Therefore, a gravity recovery circuit customized for Nalunaq's feed material has the potential to exceed the gold recovery that was achieved at El Valle.

Current Testwork Program (2020)

Samples from Nalunaq were taken in 2016, as detailed in the project's Technical Report3. The sample tested was taken from the top of pillars on the western and eastern sides of stope number 300-18 in the 310 Level West, South Block. The sample was taken such that it was representative of the true mining width, including quartz vein, hangingwall and footwall material, emulating the dilution that would occur during normal mining operations. Sampling lines were marked on the pillars using spray paint and 201.6 kg of material was collected manually. The sampled material was placed in plastic barrels for despatch.

The sample was analysed (Table 1) and contained 39.03 g/t gold and 2.40 g/t silver (Technical Report, 2016). Figure 2 illustrates the sampling location.

Table 1: Sample 300-18 assay results showing a gold grade of 39.03 g/t (Technical Report, 2016)

Sample | Original | Feed | Fraction | Wt. | Assay | Assay | Dist. | Dist. |

300.18 | 201.60 | 1.0002 | Oversize | 2.93 | 625.00 | 30.60 | 46.91 | 37.33 |

Undersize Undersize duplicate | 97.07 | 19.31 23.38 | 1.60 1.50 | 53.09 | 62.67 | |||

Sample | 100.00 | 39.03 | 2.40 | 100.00 | 100.00 | |||

Figure 2: Sample location on the 310 South Block West Level at the top of stope 300-18 (western side) (Technical Report, 2016)

Due to the relatively high-grade, the sample was diluted (50%:50%) with host rock (devoid of gold) from the Nalunaq mine to better represent the historical mine head grade. The dilution material was hand-picked from broken material in the drive at the 460 level in Target Block, and comprised of unmineralized amphibolite and granite. The diluted sample average assay was 17.7 g/t.

The 2020 test work employed the EGRG test procedure. Table 2 summarizes the results obtained from the EGRG test work undertaken at SGS. The test results show exceptional performance with 90% overall GRG for the three stages.

Table 2: Summary of the 2020 Extended GRG test results on the 300-18 Sample

GRG | Grind | GRG, |

1 | 602 | 58 |

2 | 263 | 79 |

3 | 68 | 90 |

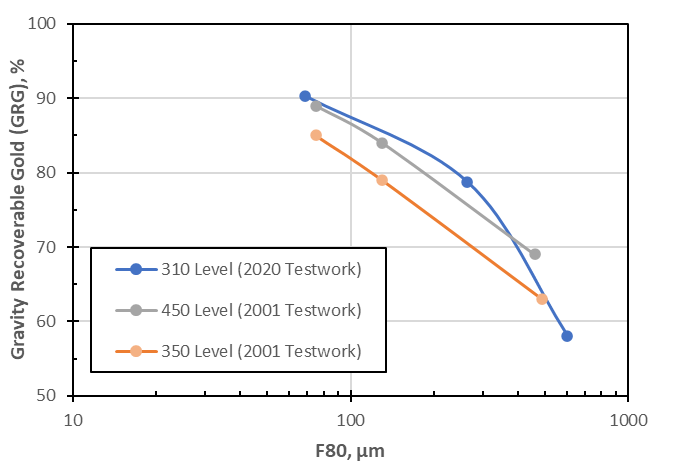

Table 3 and Figure 3 compare current and historical test work results. The latest result is slightly superior to the historical results and further confirms that the mineralized material at Nalunaq is highly amenable to gravity recovery.

Table 3: Current and Historical GRG Results on Nalunaq Ore Samples

Sample | Test Location | Year | Gold, | GRG, |

350 Level Composite | McGill University | 2001 | 9.9 | 85 |

450 Level Composite | McGill University | 2001 | 23.3 | 89 |

310 Level Sample | SGS Canada | 2020 | 17.7 | 90 |

Figure 3: Graphical representation of GRG Results on Nalunaq Ore Samples

Qualified Person and QA/QC

The scientific and technical information presented in this press release has been approved by Dr. Jarrett Quinn, P.Eng. (OIQ 5018119), Principal Metallurgist at Jarrett Quinn Consultant Inc., and James Purchase, P.Geo. (OGQ 2082), Director of Geology and Resources of G Mining Services Inc. and independent to AEX Gold Inc. for purposes of National Instrument 43-101 - Standards of Disclosure for Mineral Projects ("NI 43-101"). Mr. Quinn and Mr. Purchase are members of L'Ordre des Ingénieurs du Québec and L'Ordre des Géologues du Québec respectively, and are "qualified persons" for purposes of NI 43-101.

Sample Preparation and Assaying Techniques

Sample 300-18 was initially prepared and analysed by Wheal Jane Laboratory of Cornwall, England.

Sample preparation involved three stages of crushing and splitting. The first stage crushed material to 20 mm and split into 10 kg charges. A 10 kg split was then crushed to -5 mm, sub-sampled down to 2-3 kg and finally take down to -2.0 mm with samples split out for pulverizing and analysis.

Gold assays were performed with the M4 screened metallics method, which is a UKAS 17025 accredited method. This involves stage pulverising a 1 kg sample through a 106 µm screen until between 30 g and 50 g of oversize material remain. This entire oversize fraction along with two similar sized duplicate fractions of the undersize are then assayed to extinction in order to determine gold content. The Screened Metallics protocol reduces the likelihood of factors such as the nugget effect influencing the results of the head assay. The final assay grade was 39.03 g/t Au.

Metallurgical Procedure

Metallurgical test work was conducted by SGS Canada Inc. of Lakefield, Ontario, Canada, using the following methodology.

For the mineralized material, 36 kg of sample was split from the original sample using a rotary riffle splitter. For the dilution material, 36 kg was split out using the cone and quarter method. Both samples were crushed to 20 mesh, combined and tumbled (drum tumbler) to homogenize the sample. A rotary riffle was used to split out 10 kg charges for testwork. One charge was further split using the rotary riffle to obtain a 251.7 g sample. The sample was then split into four samples (three samples for gold fire assay to extinction (GC FAA35V) and the fourth sample for arsenic (GC XRF75F) and sulfur (GC CSA06V) analysis). All three methods are accredited under ISO/IEC 17025. The average gold assay for the three splits was 17.7 g/t. Arsenic and sulfur assayed 0.051% and 0.29%, respectively.

The EGRG test procedure involves gold recovery in three stages in a laboratory Knelson concentrator to determine the gravity recoverable gold as it is liberated at finer grinding sizes. The tailings from the subsequent stage are re-ground and processed through the gravity concentrator. Concentrates are recovered individually at each stage and analysed for gold content.

Contact Information

George Fowlie, Director and CFO

1-416-587-9801

gf@aexgold.com

Eldur Olafsson, Director and CEO

+354 665 2003

eo@aexgold.com

Camarco (Financial PR)

Gordon Poole / Nick Hennis

+44 (0) 20 3757 4980

About AEX

AEX's principal business objectives are the identification, acquisition, exploration and development of gold properties in Greenland. The Corporation's principal asset is a 100% interest in the Nalunaq Project, an advanced exploration stage property with an exploitation license including the previously operating Nalunaq gold mine. AEX is incorporated under the Canada Business Corporations Act and wholly owns Nalunaq A/S, incorporated under the Greenland Public Companies Act.

Forward-Looking Information

This press release contains forward-looking information within the meaning of applicable securities legislation, which reflects the Corporation's current expectations regarding future events and the future growth of the Corporation's business. In this press release there is forward-looking information based on a number of assumptions and subject to a number of risks and uncertainties, many of which are beyond the Corporation's control, that could cause actual results and events to differ materially from those that are disclosed in or implied by such forward-looking information. Such risks and uncertainties include, but are not limited to the factors discussed under "Risk Factors" in the Final Prospectus available under the Corporation's profile on SEDAR at www.sedar.com. Any forward-looking information included in this press release is based only on information currently available to the Corporation and speaks only as of the date on which it is made. Except as required by applicable securities laws, the Corporation assumes no obligation to update or revise any forward-looking information to reflect new circumstances or events. No securities regulatory authority has either approved or disapproved of the contents of this press release. Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

1 Note that GRG tests are standardized laboratory tests which are indicative of the gravity recovery potential of a sample, and are not meant to be used directly as parameters in an economic analysis

2 Kvaerner (2002), Nalunaq Gold Project Feasibility Study, prepared for Nalunaq I/S, Internal report, prepared by KVAERNER Engineering & Construction UK Ltd.

3 An Independent Technical Report on the Nalunaq Gold Project, South Greenland" dated March 20, 2017 (effective date of December 16, 2016), prepared for Nalunaq A/S by SRK Exploration Services Ltd.

SOURCE: AEX Gold Inc.

View source version on accesswire.com:

https://www.accesswire.com/596958/Excellent-Gravity-Recoverable-Gold-GRG-Test-Work-Results-at-Nalunaq