NORTHAMPTON, MA / ACCESSWIRE / December 14, 2023 / Nature underpins societal wellbeing by providing basic life support services and material goods such as soil, air, water, food, fuel, and fibre1, so the impacts of nature loss are wide-reaching and threaten the foundations of our global economies, livelihoods, and food systems2,3. According to the Intergovernmental Science-Policy Platform on Biodiversity and Ecosystem Services (IPBES), nature is deteriorating at rates unprecedented in human history, largely due to human activity. Around one million species are facing extinction, many within decades4. Current extinction rates are already at least tens to hundreds of times higher than what has been average over the past 10 million years5, causing scientists to declare a 'sixth mass extinction' to be underway6. Global food systems are the primary driver of this trend7. The conversion of natural ecosystems for crop production or pasture account for 90% of tropical deforestation8 and 70% of water use globally9. The Kunming-Montreal Global Biodiversity Framework (GBF) was adopted in December 2022 to halt and reverse biodiversity loss, calling for countries to take urgent action to put nature on a path to recovery by 2050 for the benefit of the planet and its people.

Why it matters

Human activity is causing unprecedented rates of deterioration of nature, leading to the possible extinction of a million species within decades. Global food systems are the primary cause of biodiversity loss10, as they drive deforestation and water use, and are also impacted by it.

Ambition

Act for nature through responsible sourcing practices and strategic partnerships to conserve and restore biodiversity, mitigate and adapt to climate change, and contribute to global water resilience11.

Targets

- Manage the impact of our value chain on nature through the implementation of a nature strategy

- Maintain our CDP Forests and Climate Change A-List leadership ranking

- Reduce the water consumption of the best practice processing lines by 50% by 2030 compared to 2019 supported by setting 9 water reduction targets for Tetra Pak facilities

Tetra Pak's role

As one of the businesses that signed the Business for Nature coalition COP-15 business statement calling for governments to adopt the Target 15 of the GBF12 to halt and reverse biodiversity loss, we believe that we have a role to play in helping to protect nature. Target 15 requires all large businesses and financial institutions to assess and disclose their risks, dependencies, and impacts on biodiversity, provide information to consumers to promote sustainable consumption and report on compliance with access and benefit-sharing mechanisms, "to progressively reduce negative impacts on biodiversity and increase positive impacts, reduce biodiversity-related risks to business and financial institutions, and promote actions to ensure sustainable patterns of production"13.

Collaborative approach

Recognising the interconnectedness of this challenge alongside nature and water, we are collaborating with our suppliers and customers to manage and mitigate our impacts on biodiversity and nature, by (1) ensuring responsible sourcing practices, (2) contributing to global water resilience14 in our own operations and supply chain, and (3) conserving and restoring ecosystems. We know that our packaging products rely heavily on the use of natural resources to be produced. The majority of the land used by our value chain comprises of forests to supply our paperboard; the remainder consists mainly of an agricultural footprint of starch crops for paperboard, sugar cane for our plant-based plastics and mining areas for aluminium foil and stainless steel.

By responsibly sourcing these materials, we can better manage the use of natural resources in a way that ensures their continued availability and minimises the harm caused by the extraction, processing, and use of these resources to the environment, communities, and workers across our value chain. Innovating across our products, filling equipment, processing lines, and services also allow us, and our customers, to reduce water-related impacts. Lastly, we are taking a cooperative approach to reverse biodiversity loss by developing and collaborating on initiatives to restore nature. Overall, we can contribute to the GBF's vision that by 2050, biodiversity is valued, conserved, restored, and wisely used, maintaining ecosystem services, sustaining a healthy planet, and delivering benefits essential for all people15.

Our progress in 2022

Nature impact assessment and strategy

Early in 2022, we joined the Corporate Engagement Program of the Science Based Targets Network (SBTN)16 to support the development of science-based targets for nature through methods, tools, and guidance to help companies transform their businesses.

We conducted an assessment of our value chain dependencies and impacts on nature. It found that the sourcing of our raw materials, including paperboard and plantbased plastics, has the highest impact on nature, compared to our operations and end use of packaging, which have a lower impact. The assessment provided a clear understanding of the drivers of biodiversity loss in our value chain, helped to prioritise strategic areas for action, and served as the basis for the development of a nature strategy. This strategy includes targets and key actions in four areas:

1) our upstream supply base;

2) our operations;

3) downstream customers and product end-of-life; and

4) transformative actions that reach beyond our value chain.

The development of the Tetra Pak Nature Strategy was a significant milestone in our work related to nature. It helps us clearly articulate our ambition related to nature through concrete targets and actions. It will also be instrumental for us to monitor and report on our progress in addressing the impacts of our value chain on nature.

Anni Vuohelainen,

Nature Project Manager, Tetra Pak

Sustainable sourcing

We are collaborating with our supply chain counterparts to increase the traceability and transparency of our sourcing, building on our certified chains of custody and our membership of voluntary sustainability standards

We are participating in an EU Horizon 2020-funded project 'Landgriffon' which uses satellite data and image-processing algorithms to support sustainable sourcing decision-making.

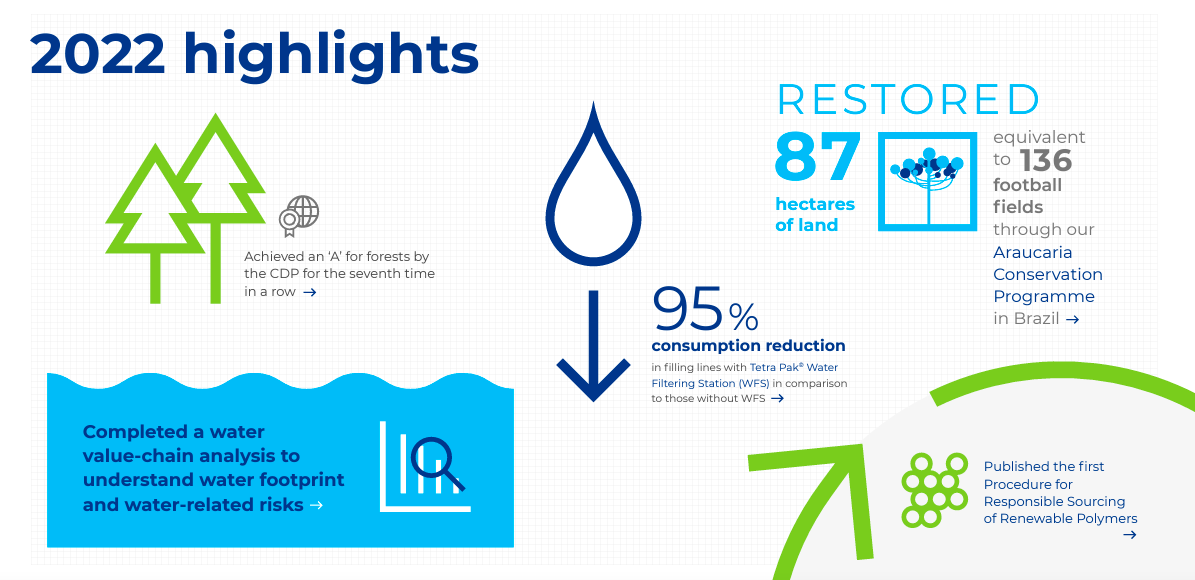

Responsible sourcing is one of the key areas where we work to address the impacts of our value chain on nature. We are developing and updating mandatory procurement requirements, such as the procedure for responsible sourcing of Liquid Packaging Board and the procedure for responsible sourcing of Renewable Polymers. For the seventh year, we achieved an 'A' from CDP Forests Disclosure, which assessed our progress in measuring and managing forest-related risks and opportunities. In 2022, 865 companies were scored, and we are proud to be one of the 25 who made the 2022 Forests A List. We strive to lead the way in corporate transparency and performance on forests and joined the CDP nature-positive challenge. Additionally, our team has been participating in a series of workshops as part of the 'Technical Working Group on Landscapes and Jurisdictional Approaches'.

READ MORE

Paperboard

On average, the paperboard content of our beverage cartons is more than 70%. Deforestation is a key driver of nature loss and a risk to our business, therefore we are committed to sourcing only from sustainably managed and deforestation-free areas17 by using the Forest Stewardship Council (FSC)18. In 2022, we sourced a total of 2.19 million tonnes of paperboard, 99%19 of which came from FSC certified forests and other controlled sources. To further verify the deforestation-free status of our paperboard sourcing, we conducted a pilot land use analysis for a sourcing area that we already know well using the Land Griffon tool, to assess how useful this tool can be for further verification of our sourcing requirements. We maintained traceability of all the wood fibre contained in our packages at a minimum to the level of processing facilities that produce the paperboard, making use of an information system that allows us to track the flow of paperboard from paper mills to our converting factories. All of our suppliers, and our own facilities, are certified with FSC Chain of Custody certification to guarantee that the paperboard in our packages comes from FSC certified forests or other controlled sources20. We also require our suppliers to report annually on the paper mills, tree species, certification status, and the country and area of origin of the wood fibre used in the paperboard supplied to us.

We have been an active member of FSC International since 2008. Via the FSC platform, we advocate for multi-stakeholder solutions involving other users and producers to secure the long-term sustainable supply of forest commodities. In the 2022 General Assembly week we participated in three standards consultation processes as well as taking part in a range of membership meetings, using our voting power and membership voice to drive change and simplification. As members of FSC we support the FSC 2026 strategy to increase certified forests from 220 million hectares to 300 million hectares21.

We have also engaged in an initiative to fast-track Biodiversity Assessments of FSC-certified forests, launched at COP-15 in Montreal. The project aims to evaluate the biodiversity value associated with FSC forest management certification and strengthen the monitoring of forest biodiversity to further support the assessment of FSC's contribution to biodiversity conservation.

Aluminium

In 2022, 99.6% of our aluminium volume was delivered by suppliers certified by the Aluminium Stewardship Initiative (ASI) Performance Standard, which addresses GHG emissions, water use, biodiversity, human and labour rights, and OHS, and we were recertified without any nonconformances.

Plant-based plastics

100% of the plant-based plastics used in our products is made from sustainably sourced sugarcane certified by Bonsucro. Bonsucro certification promotes sustainable production, processing and trade of sugarcane around the world and enables our customers to make stronger and more comprehensive sustainability claims about our products that contain plant-based polymers. In 2019, we were the first company in the food packaging and processing industry to source plant-based plastic responsibly using the Bonsucro Chain of Custody Standard. We further strengthened our approach in 2022 by publishing our first Procedure for responsible sourcing of renewable polymers. Additionally, we are represented on the Bonsucro Members' Council and gave input on behalf of the End User membership class to the revised Bonsucro Production Standard v5.1 to ensure that biodiversity and ecosystem services are mapped, risk-assessed and managed in sugarcane production areas.

Water management

We are contributing to a water-secure22 world by leveraging expertise, technology, and partnerships towards building secure, resilient, and sustainable food systems23 to reduce water-related impacts of our packaging and processing solutions. We work to reduce impacts on local water resources, contributing to solving shared water challenges in basins at risk24 across our entire value chain.

Analysing our water-related risks across the value chain

Across 2022, we ran a Water Value Chain Assessment to better understand our water-related risks and impacts along the entirety of the value chain. We interact with water in three main areas: usage upstream, connected with the production of packaging raw materials; usage at our operations; and usage linked to processing and packaging food at our customers' sites25. The analysis showed that 55% of our corporate water footprint comes from upstream purchases, such as paperboard, fossil-based polymers, and aluminium, followed by 36% related to direct and indirect water use by customers using Tetra Pak equipment. Our direct water consumption from manufacturing sites represents no more than 1% of the corporate footprint. The analysis also quantified the risk in our manufacturing sites for water availability and quality as well as water sanitation and hygiene. As a result, we have set 9 water targets across our value chain covering direct use of water in Tetra Pak facilities, use of products by customers, and water use by suppliers.

Reducing direct use of water in Tetra Pak facilities

We introduced an internal Water Management Procedure providing guidance and mandatory requirements for all our manufacturing sites with its aim being to engage sites to operate in line with water stewardship standards, including monitoring of water discharge quality and water withdrawal quantities26. Further to this, Tetra Pak sites address water-related impacts both locally, through identification of water improvement opportunities, as well as from a centrally managed approach via our Facilities & Real Estate Management (FREM) organisation.

The increase in water withdrawal between 2022 and 2021 is attributed to our cooling system in our converting factory in Sunne, Sweden. The system uses surface water from a nearby lake for production cooling, after which the water is returned to the same lake. As a result, our net water consumption27 is not significantly affected, as it decreased to 1066ML compared to 1405ML in 2021.

READ MORE

Part of this decrease can be attributed to our Kunshan site in China which achieved a 10% water reduction and over 2.8 million litres of water savings in 2022 by mapping the possibility of water recycling within municipal water consumption and finding a solution to reuse the waste-treated water in the cooling tower.

Saving wastewater and reducing product losses with membrane filtration solutions

In an effort to help our customers reduce water use in their operations, in 2022, we worked with two dairy customers on their membrane filtration system to drive efficiency. The first customer, a dairy that produces ingredients, has operated a membrane filtration system to reduce milk product losses by 308,000 litres annually, recover 7,800 litres of water daily, and ultimately reduce wastewater volume requiring treatment by 730,000 litres annually. The dairy collects white water from different processes daily. Using membrane filtration, it can now concentrate the white water to reduce milk product losses and recover water, which can be used for cleaning processes, reducing the need for fresh water. Similarly, we helped a dairy-producing ingredients customer to optimise its membrane filtration system to support the reduction of wastewater discharged, chemicals used, and energy consumed, as well as provide the capacity and capability to purify spent caustic from evaporators for reuse over several years

Reducing 95% water by using water filtration

Our solutions are allowing further water consumption reduction for our customers when packaging their products. One example is our Tetra Pak® Water Filtering Station (WFS) in filling lines with a 95% water consumption reduction in comparison to those without WFS. This is achieved by the WFS lines removing lubrication, residues from packaging material, hydrogen peroxide and alkaline pH, and then circulating clean water free from all contaminants back into the system. Improving water quality can also increase the lifespan of the components in the filling machines because filtered water is free from H2O particles, oil, grease, and other contaminants that damage and corrode parts.

READ MORE

Ecosystem restoration

We are engaging in on-the-ground action by developing and supporting collaborations to restore nature, focusing on a nature-based28 land restoration project in Brazil. Our Araucaria Conservation Programme was developed in collaboration with Apremavi, a Brazilian NGO specialising in conservation and restoration projects since 1987. The initiative is set to restore up to 7,000 hectares - equivalent to 9,800 football pitches - of degraded land over ten years in the Forest of Araucarias in the Atlantic Forest, one of the richest biomes and the second most endangered in the world. The project involves a collaboration of stakeholders to advance shared social, economic, and environmental objectives across multiple economic sectors and land uses.

In 2022, a pilot site of 87 hectares of land in the municipality of Urubici, Santa Catarina state was restored29. This is equivalent to 136 football fields, surpassing the initial goal of 80 hectares. This comes at a time when around 3.75 million hectares of tropical primary rainforests were lost in 2021, 1.5 million hectares of which occurred in Brazil30. Of the 87 hectares, 47 hectares of seedlings were planted, and another 40 hectares are being actively monitored for natural regeneration. Both restoration areas have been protected with a fence to stop livestock from pasturing on the new seedlings and regenerated vegetation.

Land restoration also plays a vital role in combating climate change as trees absorb and store carbon dioxide as they grow. With forests currently responsible for absorbing 30% of all carbon emissions in the world31, restoration projects like the one in the Atlantic Forest can help reduce the levels of carbon dioxide in our atmosphere and help reverse climate change as identified by the IPCC in their latest 2023 AR6 summary report. The aim is to include certification of up to 13.7 million hectares under international voluntary carbon and biodiversity standards for carbon sequestration measurement32.

READ MORE

Learn more about what is next for Tetra Pak here.

1 IPBES. (2019). Global Assessment Report of the Intergovernmental Science-Policy Platform on Biodiversity. In E. S. Brondízio, J. Settele, S. Díaz, & H. T. Ngo (Eds.), IPBES secretariat. IPBES secretariat, Bonn, Germany.

2 Herweijer, C., et al. "Nature risk rising: Why the crisis engulfing nature matters for business and the economy." World Economic Forum and PwC. https://www3.weforum.org/docs/WEF_New_Nature_ Economy_Report_2020.pdf

3 FAO. 2019. The State of the World's Biodiversity for Food and Agriculture, J. Bélanger & D. Pilling (eds.). FAO Commission on Genetic Resources for Food and Agriculture Assessments. Rome. 572 pp.

4 IPBES. (2019). Global Assessment Report of the Intergovernmental Science-Policy Platform on Biodiversity. In E. S. Brondízio, J. Settele, S. Díaz, & H. T. Ngo (Eds.), IPBES secretariat. IPBES secretariat, Bonn, Germany.

5 IPBES. (2019). Global Assessment Report of the Intergovernmental Science-Policy Platform on Biodiversity. In E. S. Brondízio, J. Settele, S. Díaz, & H. T. Ngo (Eds.), IPBES secretariat. IPBES secretariat, Bonn, Germany.

6 Ceballos, G., Ehrlich, P. R., Barnosky, A. D., García, A., Pringle, R. M., & Palmer, T. M. (2015). Accelerated modern human-induced species losses: Entering the sixth mass extinction. Science Advances, 1(5), 9-13.

7 Benton, T.G., et al. (2021). Food system impacts on biodiversity loss: Three levers for food system transformation in support of nature. Chatham House. Source: https://www.chathamhouse.org/sites/default/files/2021-02/2021-02-03-food-system-biodiversity-loss-benton-et-al_0.pdf

8 Pendrill, Florence, et al. "Disentangling the numbers behind agriculture-driven tropical deforestation." Science 377.6611 (2022): eabm9267.

9 The State of the World's Land and Water Resources for Food and Agriculture - Systems at Breaking Point. Synthesis Report 2021. Rome (2021),10.4060/cb7654en

10 Benton, T.G., et al. (2021). Food system impacts on biodiversity loss: Three levers for food system transformation in support of nature. Chatham House. Source: https://www.chathamhouse.org/sites/ default/files/2021-02/2021-02-03-food-system-biodiversity-loss-benton-et-al_0.pdf

11 "The private sector can play a critical role in building system resilience, as businesses can drive resilience at the local level (on-site resilience), through their supply chains (supply chain resilience) and beyond their operation (system resilience)". Source: Water Resilience Assessment Framework Corporate Guidance. https://www.globalcompact.de/fileadmin/user_upload/Water_Resilience_Assessment_ Framework.pdf

12 Source: https://www.cbd.int/gbf/

13 Source: https://www.cbd.int/article/cop15-cbd-press-release-final-19dec2022

14 "The private sector can play a critical role in building system resilience, as businesses can drive resilience at the local level (on-site resilience), through their supply chains (supply chain resilience) and beyond their operation (system resilience)". Source: Water Resilience Assessment Framework Corporate Guidance https://www.globalcompact.de/fileadmin/user_upload/Water_Resilience_Assessment_Framework.pdf

15 Source: https://www.cbd.int/article/cop15-final-text-kunming-montreal-gbf-221222

16 https://sciencebasedtargetsnetwork.org/wp-content/uploads/2020/11/Science-Based-Targets-for-Nature-Initial-Guidance-for-Business.pd

17 Tetra Pak ensures that wood fibre in the paperboard shall not originate from areas where there has been deforestation after 31 December 2020. Deforestation-free areas are areas where there has been no loss of natural forest as a result of: i) conversion to agriculture or other non-forest land use; ii) conversion to a tree plantation; or iii) severe and sustained degradation. Source: https://www.tetrapak.com/content/dam/tetrapak/publicweb/gb/en/sustainability/Tetra-Pak-Procedure-Responsible-Sourcing-Liquid-Packaging-Board-2023.pdf

18 The FSC license code for Tetra Pak is FSC C014047

19 The remaining 1% was sourced from Russia during the time when FSC certificates were suspended due to the Russian invasion of Ukraine. Tetra Pak ended all of its operations in Russia on July 26th, 2022, and no longer sources any paperboard or wood fibre from Russia

20 Controlled sources are FSC controlled wood. This wood originates from low-risk sources which exclude illegally harvested wood, wood harvested in violation of traditional and human rights, wood harvested in forests in which high conservation values are threatened by management activities, wood harvested in forests being converted to plantations or non-forest use and wood from forests in which genetically modified trees are planted. Controlled wood can make up a maximum of 30% of FSC MIX certified wood fibre. More information: https://fsc.org/en/fsc-mix-label-and-controlled-wood

21 Source: https://fsc.org/sites/default/files/2020-12/FSC%20GLOBAL%20STRATEGY%202021-2026%20%28English%20version%29%20%282%29.pdf

22 UN Water defines water security as "the capacity of a population to safeguard sustainable access to adequate quantities of and acceptable quality water for sustaining livelihoods, human well-being, and socio-economic development, for ensuring protection against water-borne pollution and water-related disasters, and for preserving ecosystems in a climate of peace and political stability". Source: https://www.unwater.org/publications/water-security-and-global-water-agenda

23 The Food and Agriculture Organization of the United Nations defines food systems as "the entire range of actors and their interlinked value-adding activities involved in the production, aggregation, processing, distribution, consumption and disposal of food products that originate from agriculture, forestry or fisheries, and parts of the broader economic, societal and natural environments in which they are embedded". Source: https://www.fao.org/3/ca2079en/CA2079EN.pdf

24 Basins at risk are identified following the SBTN methodology, based on eight different indicators across water quantity, quality and wash. For each indicator, a score between 1 and 5 is attributed. Within these three categories, one indicator with a score of 3 or above indicates that the basin is at risk. Source: https://sciencebasedtargetsnetwork.org/resources/

25 For Tetra Pak sites, water is supplied either by third party (municipal supply), by own ground wells, or from surface water. Besides water use at all our sites for sanitary purposes, water is also used for industrial operations. Common uses include cooling systems, washing activities, equipment testing activities, and gardening. Water discharge is done either to external wastewater treatment (municipal or third-party wastewater facilities), or to surface water after on-site wastewater treatment.

26 Each Tetra Pak site is locally responsible for ensuring that it meets all local water related regulatory requirements.

27 Water consumption is the portion of water use that is not returned to the original water source after being withdrawn. Consumption occurs when water is lost into the atmosphere through evaporation or incorporated into a product or plant (such as a corn stalk) and is no longer available for reuse. Source: https://www.wri.org/insights/whats-difference-between-water-use-and-water-consumption

28 Solutions that are inspired and supported by nature, which are cost-effective, simultaneously provide environmental, social and economic benefits and help build resilience. Source: https://research-and-innovation.ec.europa.eu/research-area/environment/ nature-based-solutions_en

29 Verification of restoration status will be undertaken by Apremavi, our restoration partner.

30 World Resources Institute: Global Forest review. (2022). Source: https://research.wri.org/gfr/latest-analysis-deforestation-trends

31 United Nations Climate Action. Source: https://www.un.org/en/climatechange/science/climate-issues/land

32 The uptake and storage of carbon. Trees and plants, for example, absorb carbon dioxide, release the oxygen and store the carbon. Source: https://www.eea.europa.eu/help/glossary/eea-glossary/carbon-sequestration

View additional multimedia and more ESG storytelling from Tetra Pak on 3blmedia.com.

Contact Info:

Spokesperson: Tetra Pak

Website: https://www.3blmedia.com/profiles/tetra-pak

Email: info@3blmedia.com

SOURCE: Tetra Pak

View the original press release on accesswire.com