-- Paving the Way for the Energy of the Future, a Major Step towards Series Production of Key Components for Fusion Reactors --

- With the completion of the prototype, preparations are being made for mass production of the units

- MHI and QST collaborate on production of key components for ITER, steadily advancing fusion energy development

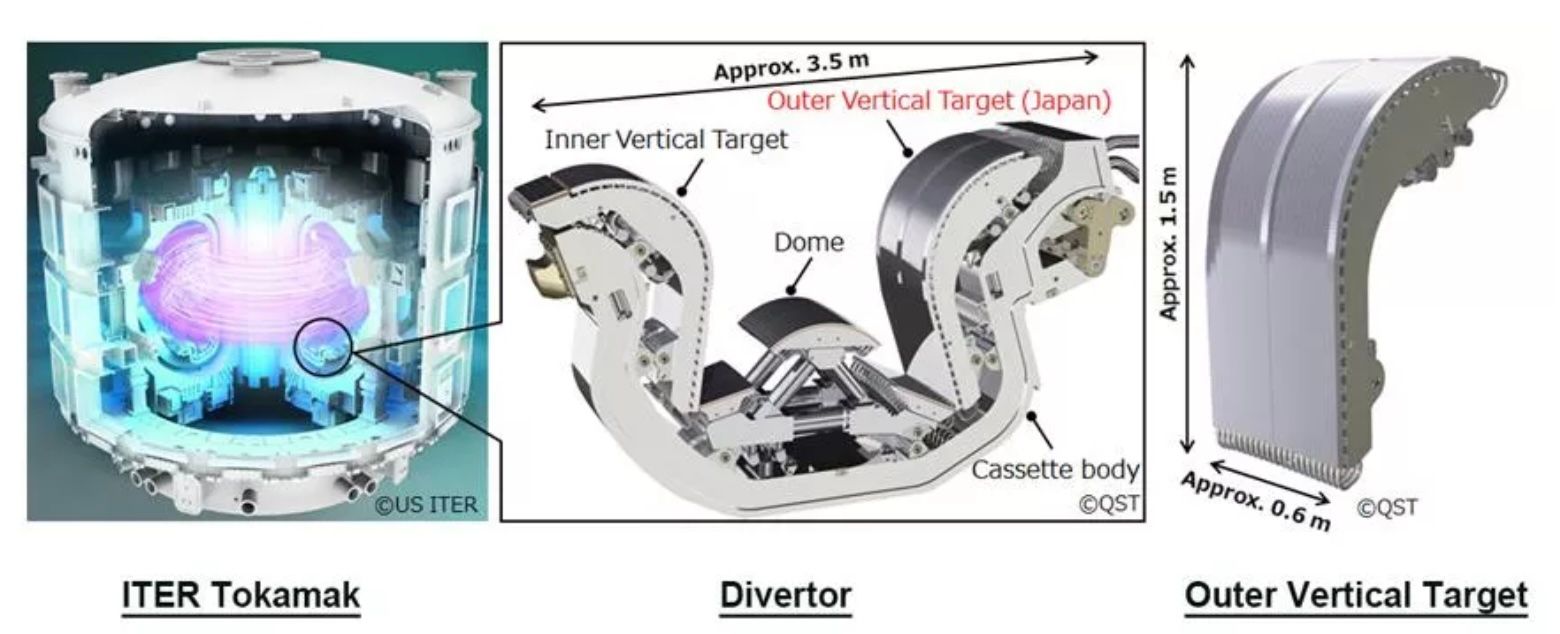

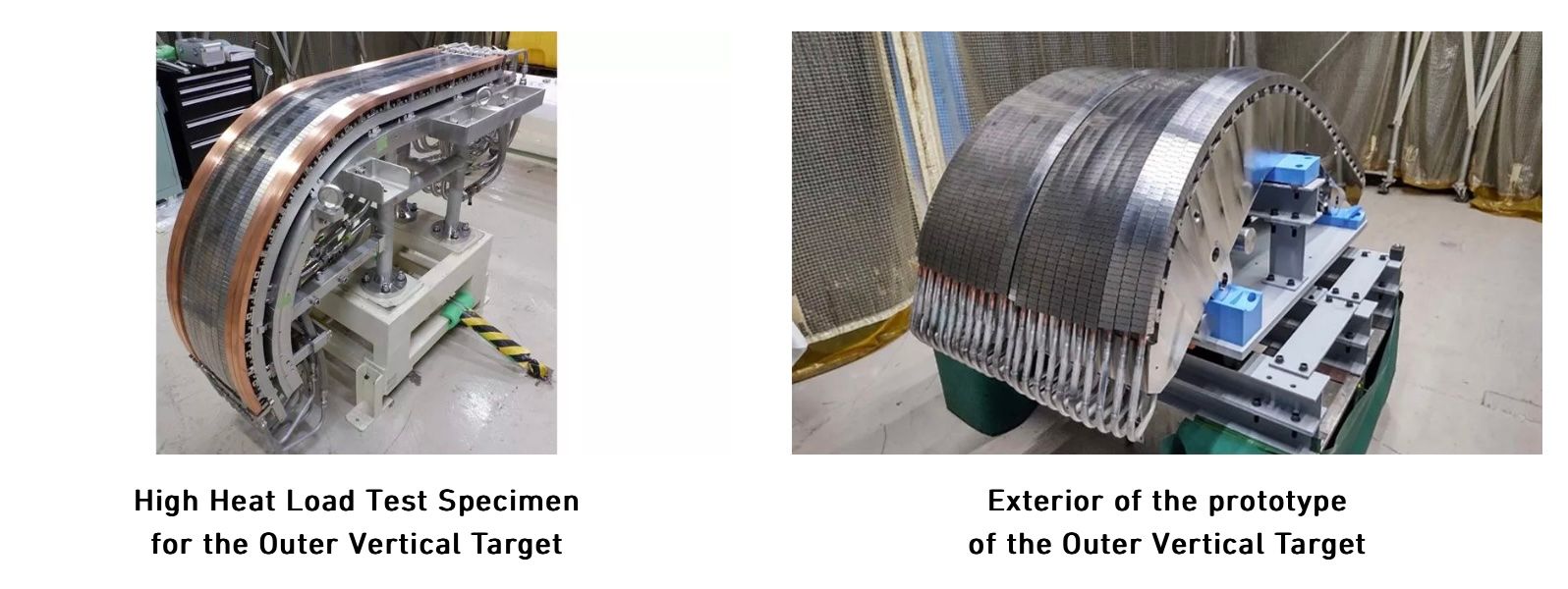

TOKYO, July 31, 2024 - (JCN Newswire) - Mitsubishi Heavy Industries, Ltd. (MHI) and National Institutes for Quantum Science and Technology (QST), as part of the effort to manufacture components to be used in the ITER experimental fusion reactor(1),(2) under construction in southern France, have completed a prototype of the Outer Vertical Target (OVT) since the prototype manufacturing was started in June 2020. Here, the OVT is one of the key components of the Divertor. Last year, the high heat flux test on plasma facing units of the OVT was performed by the ITER Organization and heat removal performance was confirmed, and then, our manufacturing processes of the PFU were certified by the ITER Organization. MHI has now completed a prototype that will be a full-scale mock-up of the OVT and is ready for series production. MHI and QST will utilize the technology acquired through production of this prototype and apply their full efforts toward manufacturing the units(3), contributing to the advancement of the ITER project.

|

|

The divertor is one of the most crucial components in magnetic field confined fusion reactors such as tokamaks. It plays an important role in removal or exhaust of unburned fuel in the core plasma and impurities such as helium (He) generated by the fusion reaction, in order to sustain the fusion reaction in a stable manner.

The heat load on the divertor target reaches a maximum of 20MW/m2. This is equivalent to the surface thermal load on an asteroid probe during re-entry into the atmosphere, and approximately 30 times the surface thermal load on a Space Shuttle. The divertor is the component of the tokamak device that directly receives plasma, so it is used in severe environments where it is exposed to the heat load and high energy particle loading from the plasma. For this reason, it requires special materials such as tungsten, which has a high melting point but is difficult to be machined, as well as high-precision fabrication and processing technologies to produce the structures. In addition, the plasma facing surface is processed with minute shapes, and accuracy of 0.5 mm or less is required for the inclination, level difference, and clearance of each plasma facing material, as well as the overall shape. QST, backed by its innovative R&D capabilities, has been focusing on the R&Ds of divertors from before the ITER project, and MHI has leveraged its outstanding manufacturing capabilities to successfully produce a prototype of the OVT, which is the most difficult component of ITER's in-vessel components from a viewpoint of manufacturability.

QST has previously worked on the production of toroidal field (TF) coils, another core component of ITER, and shipped all nine TF coils to the ITER site by the end of 2023. MHI was responsible for five of the nine TF coils.(Note4) MHI is proceeding with series production of the OVT to be delivered by QST to ITER, and will deliver six units to QST in FY 2025. With the completion of the prototype for the OVT of the Divertor, industry, academia, and government in Japan are making a concerted effort and taking a more proactive role in the ITER project, which is working to develop the technologies that will be crucial for the sustainable development of the world.

(1) Fusion is the source of energy that enables the sun to keep shining. The ultimate goal is achieving fusion on Earth. Fusion reactions fuse light atomic nuclei (deuterium and tritium) in a plasma environment into the heavier element of helium. Fusion energy emits zero carbon dioxide, and the source of fuel can be extracted from seawater in virtually unlimited quantities (lithium from which tritium is derived, and deuterium). Fusion energy is expected to provide fundamental solutions to many of the world's energy and environmental problems.

(2) The ITER Project is an international megaproject to demonstrate, both scientifically and technologically, the feasibility of fusion energy. Seven participating parties (Japan, the EU, the U.S., Russia, Korea, China, and India) are constructing ITER in Saint-Paul-les-Durance, France, with a target for full-fledged operational startup of nuclear fusion combustion. Japan plays a crucial role in the development and manufacture of divertors, TF coils, and other major components for ITER. QST, the ITER Japan domestic agency for the ITER Project designated by Japanese government, oversees the procurement of these components. www.mhi.com/news/211213.html

(3) Of the 58 units QST will deliver to ITER, MHI is responsible for the production of all 18 units QST has ordered.

(4) For more information on the TF coils that QST ordered from MHI, see the following press release. www.mhi.com/news/210524.html

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world's leading industrial groups, spanning energy, smart infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on spectra.mhi.com.

Source: Mitsubishi Heavy Industries, Ltd.

Copyright 2024 JCN Newswire . All rights reserved.

© 2024 JCN Newswire