Using "Smart Connections" Solutions to Address the Various Challenges Faced by Logistics Facilities

- Demonstration to be conducted at MHI's LogiQ X Lab demonstration facility, Kirin Group's Nishi-Nagoya facility and other sites, with scheduled completion by March 2026

- Providing solutions to the challenges posed by regulatory changes in 2024, including a shortage of operators at logistics sites, and reduced working hours for truck drivers

TOKYO, Aug 22, 2024 - (JCN Newswire) - Mitsubishi Heavy Industries, Ltd. (MHI), together with Kirin Group companies Kirin Beverage Co., Ltd. and Kirin Group Logistics Co., Ltd., in August will begin a joint demonstration aimed at establishing elemental technologies for the automation of inbound and outbound processes at beverage warehouses, and the loading and unloading of trucks. The joint demonstration will be conducted at LogiQ X Lab, a demonstration facility located within Yokohama Hardtech Hub (YHH), MHI's co-creation space in Honmoku, Yokohama, and at Kirin Group Logistics sites. The demonstration is scheduled to conclude by March 2026.

|

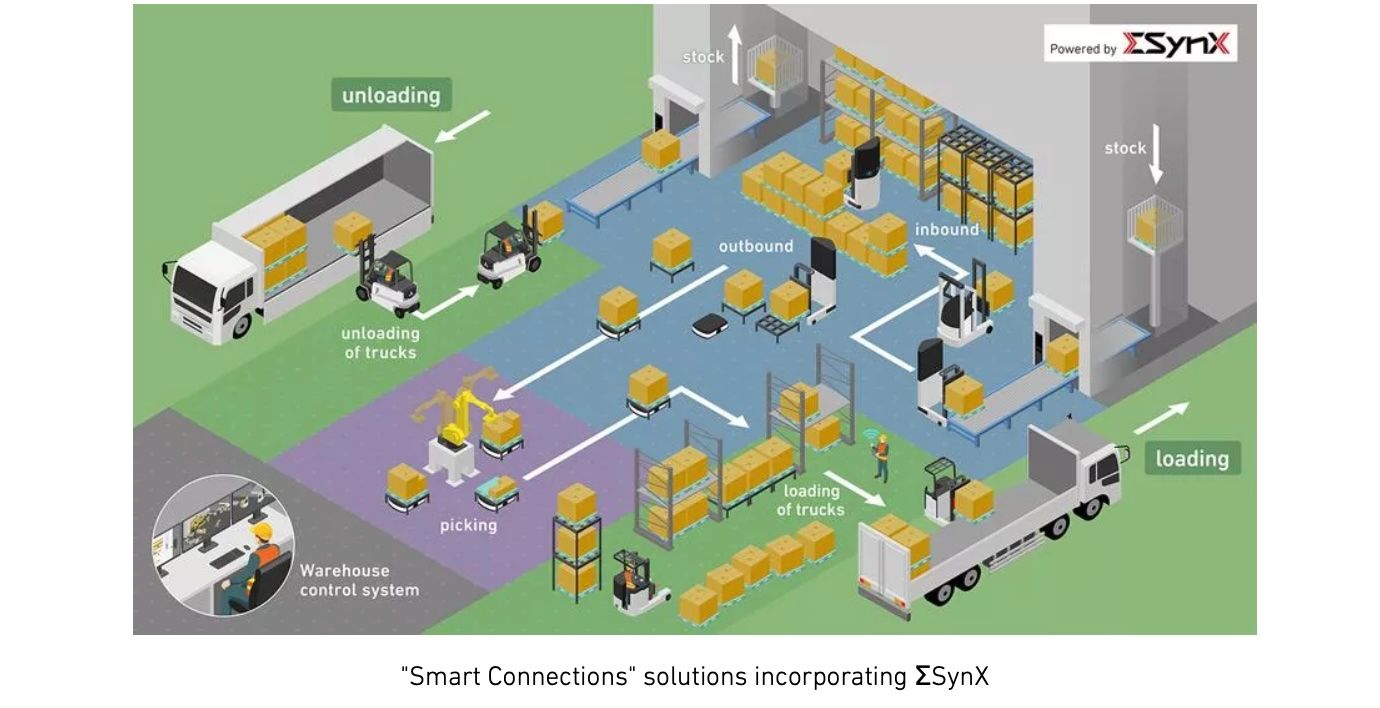

For this demonstration, as part of the "Smart Connections" solutions incorporating the SynX (Sigma Syncs) technology(Note1) that MHI is currently researching and developing, MHI will utilize a new type of unmanned forklift that is currently under development equipped with SynX, with the aim of establishing elemental technologies that enable flexible autonomous operation and safe human-machine coordination, including appropriate load assortment in warehouse work, altering of operational routes in response to changes in placement locations and storage conditions, and highly efficient storage methods. Through this joint demonstration, MHI aims for future automation of the entire cargo handling process, from the unloading of trucks to handling of inbound and outbound warehouses process, and loading onto trucks.

MHI is steadily advancing efforts to utilize "Smart Connections" solutions incorporating the SynX (Sigma Syncs) technology for automation and intelligence of normal logistics warehouse work, which up to now has been conducted safely and efficiently through the expertise, experience and skills of operators, focusing on the three areas of picking, inbound and outbound processes, and the loading and unloading of trucks. Following picking, which is the handling of cargo in warehouses, MHI will pursue development and verification to support the implementation of "Smart Connections" solutions for warehouse operations in the logistics industry. MHI and Kirin Group conducted a joint demonstration of automated picking from November 2022 to June 2023.(Note2) This demonstration verified its effectiveness at logistics sites, and an automated picking solution is scheduled to start operation at Kirin Group's Ebina Logistics Center in Kanagawa Prefecture from December 2024. This new joint demonstration being conducted by the two companies will accelerate the response to the challenges posed to the logistic industry by regulatory changes implemented in 2024.

Going forward, through coordination with Kirin Group for this demonstration program, MHI will work to provide solutions for the various issues faced by the beverage industry due to regulatory changes, such as the shortage of logistics operators, the need for improvement in working conditions, and reducing truck driver working hours and wait times.

(1)SynX (Sigma Syncs) is MHI's standard platform for synchronizing and coordinating various types of machinery systems. It consolidates a host of digital technologies that enable optimized operation by making machinery systems intelligent. For more information, please refer to the following press release. www.mhi.com/news/23100501.html

(2) For more information on the joint demonstration with Kirin Group for an automated picking solution, please refer to the following press release. www.mhi.com/news/22112101.html

Overview of the Joint Demonstration

Implementation period: August 2024, through March 2026

Demonstration sites: MHI's LogiQ X Lab demonstration facility at Yokohama Hardtech Hub (YHH), MHI's demonstration facility at Kobe Shipyard, and Kirin Group Logistics facilities such as Nishi-Nagoya and Amagasaki.

Content for the demonstration

- Determining of operational processes, including manned work, assuming the introduction of warehouse inbound and outbound process solutions

- Determining of operational processes, including manned work, assuming the introduction of unmanned forklifts for loading and unloading trucks

- Determining of safety concepts, rules, operating conditions, and other standards for collaborative work with manned and unmanned forkliftsTags: Sigma SynX,Smart Infrastructure

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world's leading industrial groups, spanning energy, smart infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on spectra.mhi.com.

Source: Mitsubishi Heavy Industries, Ltd.

Copyright 2024 JCN Newswire . All rights reserved.

© 2024 JCN Newswire