Aiming to achieve both efficiency and light weight in traction motors, contributing to carbon neutrality

TOKYO, Sept 19, 2024 - (JCN Newswire) - Hitachi Industrial Products, Ltd. ("Hitachi Industrial Products") has commercialized the world's first(1) copper die-cast(2) rotor(3) for railway traction motors as light weight of rotor. By adding weight-reduction technology to the high-efficiency technologies that Hitachi Industrial Products already possesses, we will contribute to further energy savings and reduced environmental impact of railway vehicle operation.

|

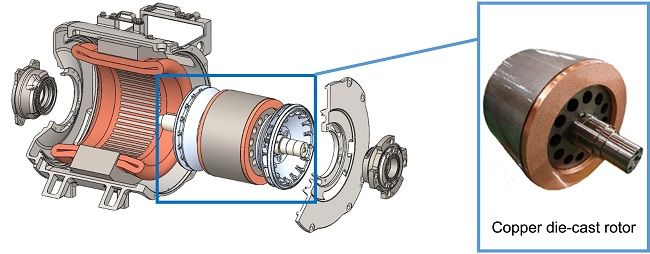

| Internal structure of traction motor with copper die-cast rotor |

To further reduce the weight of rotors, a component of traction motors, Hitachi Industrial Products has developed a copper die-cast rotor for railway traction motors.

The copper die-cast rotor is manufactured by die-casting copper, a conductor, and is approximately 15 kg lighter in weight than conventional rotors in which copper bars and end rings(4) are brazed together ("copper bar type"). Going forward, this new rotor will be applied to railway projects.

(1) According to our research (using copper die-cast rotors in traction motors for railway vehicles)

(2) Die casting: A casting method in which molten metal is poured into a mold, and shaped under pressure.

(3) Rotor: A rotating part that constitutes a traction motor. Here, this refers to a squirrel-cage rotor.

(4) End ring: A ring material that electrically connects and shorts both ends of the rotor conductor copper bars. Copper or brass is applied.

Development Background

Hitachi Industrial Products' conventional lineup of traction motor rotors consists of two types: the copper bar type, which is constructed by inserting a rod-shaped copper bar into a slot in the iron core, and the aluminum die-casting type, which is manufactured by die-casting an aluminum conductor.In order to contribute to the realization of a carbon-neutral society, we are promoting the improvement of the efficiency of traction motors.For our highly efficient products, we use copper bar type rotor conductors made of copper material, which has lower losses than aluminum.To achieve both efficiency and weight reduction, we considered adopting the copper die-casting, and could reduce the number of parts by simplifying the structure while maintaining the efficiency achieved by using copper material. However, because the melting point of copper (approximately 1086degC) is higher than that of aluminum (approximately 660degC), the temperature of the molten copper becomes very high, making it extremely difficult to cast with good quality. In addition, because the rotor is intended for traction motors for railway, die-casting into larger rotors is necessary, which was an issue.By applying the aluminum die-casting technology it has cultivated to copper, repeatedly prototyping and verifying copper die-cast rotors over several years, Hitachi Industrial Products established suitable design and verification methods for railway vehicle traction motors, developed and commercialized high-quality copper die-cast rotors.

Exhibitionat "InnoTrans 2024, the International Railway Technology Trade Fair"

The copper die-cast rotor will be exhibited at the International Railway Technology Trade Fair - InnoTrans 2024, which will be held in Berlin, Germany from Tuesday, September 24th to Friday, September 27th, 2024. For more information, please visit the Hitachi Industrial Products website: "Exhibiting at the International Railway Technology Trade Fair - InnoTrans 2024" (https://www.hitachi-ip.com/news/20240904.html)

About Hitachi Industrial Products, Ltd.

Hitachi Industrial Products contributes to improving social, environmental values of our customers throughout the product business in Connective Industries sector in Hitachi that digitally connects products in a wide range of fields such as industrial distribution, water infrastructure, healthcare, home appliances, air conditioning systems, measurement, analysis systems, and building systems. For details, please visit the Hitachi Industrial Products Ltd. website (www.hitachi-ip.com/)

Source: Hitachi, Ltd.

Copyright 2024 JCN Newswire . All rights reserved.

© 2024 JCN Newswire