NORTHAMPTON, MA / ACCESSWIRE / December 16, 2024 / International Paper Company

Originally published in International Paper's *Thinking Inside the Box* white paper

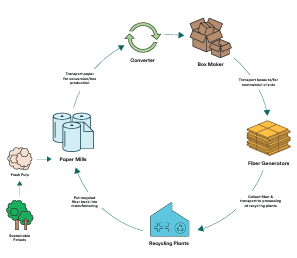

International Paper implements circular principles and practices throughout its value chain to ensure that its products are responsibly sourced, recovered and recycled into new boxes.

The company's Vision 2030 goals align with the principles of the circular economy - and its actions demonstrate a commitment to progress and growth in the sustainability space. By 2030, IP aims to source 100% of its fiber from responsible sources, meaning sources that conform to 3rd party certification standards. The company also aims to create products that are 100% reusable, recyclable and compostable.

Setting measurable sustainability goals helps packaging companies align to the principles of a circular economy: to eliminate waste and pollution, circulate products and materials and regenerate nature.

Eliminate Waste and Pollution

Much of the world economy operates in a way that converts raw materials to products and then eventually disposes these products as waste. Waste accumulates and becomes unusable. At the same time, landfills are one of the largest producers of GHG emissions. Circular economic thinking treats waste as a "design flaw"20, which can be mitigated and eventually solved through adaptations to the use and reuse of products.

Responsible use of natural resources and transparency in sourcing are essential to meeting increased demand for wood fiber without destroying valuable forests. The recovery and recycling of fiber-based products is integral to "reducing consumption footprints, providing sustainable products and thereby contributing to creating more sustainable lifestyles."21

A core component of any circularity strategy are products that enjoy multiple lives through repeated cycles of reuse, recovery and recycling, and the assurance that any byproducts of the manufacturing process are put to good use. Every year, IP uses five million tons of recovered fiber to make new fiber-based packaging, making International Paper one of the world's largest users of recovered fiber. Additionally, nearly 50% of the company's manufacturing waste is diverted from landfills each year for beneficial use. For example, the ash created from burning tree bark and other residuals is used to stabilize pH levels in farmland. Dry ash can be used in road construction and in the manufacturing of concrete. Other wood byproducts are used to make everyday products such as paints, fabrics, lubricants and even cosmetics.

In International Paper's Europe, Middle East and Africa (EMEA) region, the company is promoting sustainable and renewable products by developing solutions for all types of packaging. As a result of these efforts in EMEA, IP's corrugated products have replaced 765 tons of plastics in 2022, and 1,410 tons replaced since the beginning of the decade.

Circulate Products and Materials

International Paper occupies a unique position in the market as both a producer of fiber-based products and a consumer of reclaimed cardboard. As such, the company has a marked impact on the overall industry for recycled cardboard.

There are few products in the world where a used product can generate revenue, but cardboard is one. In the customer success story below, International Paper was able to solve the customer's challenges created by China's withdrawal from the import waste market, generate revenue from would-be waste product, and close the circularity loop in its sustainable packaging story.

A national wholesaler was faced with the challenge of needing to diversify its recycling partners. A single distribution center uses tens of thousands of tons of cardboard each year. Without an outlet, its used cardboard would accumulate on its loading docks and in its parking lots, impeding business, creating a fire hazard and otherwise threatening human safety. As both an aggregator and manufacturer, International Paper offered end-to-end circularity. International Paper has a nationwide network of 18 recycling plants to handle the old corrugated containers (OCC) volume produced by a national wholesaler of this scale. IP also had the transportation infrastructure to step in from day one and guarantee movement of 100% of this wholesaler's OCC volume from its distribution centers nationwide- thousands of tons per year. And, as the largest producer of containerboard in the country, making as much as a third of all U.S. corrugated packaging, only International Paper could also guarantee that this wholesaler's OCC would be appropriately recycled and reused. With its scale, national network and recycling expertise, International Paper was able to offer an end-to-end solution.

Another example of a circular customer solution comes from Italy where IP collaborated with long-standing customer Colgate-Palmolive to design a circular supply chain solution to decrease waste and increase recycling. A local transport company collects paper and corrugated packaging scraps from the Colgate-Palmolive plant and delivers them to a local recycled paper manufacturing facility. IP's Pomezia, Italy box plant then transforms it into the Circular Box, which is used for transporting personal care products. The result is a closed and sustainable circular supply chain. The Circular Box was chosen as a finalist in the Best Packaging 2022 contest, organized by the Italian Packaging Institute (Istituto Italiano Imballagio) in collaboration with Conai (National Packaging Consortium).22

Positively Impact Nature

1.6 billion people worldwide depend on healthy forests for their livelihoods.23 Because the creation of paper-based products begins in the forest, packaging companies should be committed to using only fiber from sustainably managed forests, as well as recovered fiber.

It all starts with responsible and transparent sourcing. At IP, the fiber supply team has developed an internal fiber procurement mapping tool called ForSite, an industry-leading platform that exemplifies transparency, risk mitigation and targeted collaboration. ForSite enables IP to know where its wood is coming from and ensures that the right resources and decisions are made before the fiber enters the mill system.

This system guides IP's responsible fiber procurement on non-certified forestland in the U.S. It ensures that conservation approaches, similar to those practiced on third-party certified lands, are incorporated in forest management and harvest practices on non-certified lands.

ForSite uses Geographic information system (GIS) technology to display and organize spatial data within the complex network of family-owned and institutional "stands" that make up the forests where IP procures its fiber. ForSite data includes an array of environmental and spatial attributes, including rare, threatened and endangered species, priority forest types and landscapes, soil types, topography and hydrology, satellite imagery and optimized delivery location. This data is presented in an easy-to-use mobile app, which allows fiber supply team members to make informed decisions prior to the fiber entering IP's supply chain. In addition, ForSite assists partners in the tree farming industry and conservation groups.

By knowing the exact location of the direct fiber purchased, IP can ensure not only that its fiber is derived from sustainably managed forests, but also that it is delivered to the most cost-effective facility.

As one of the world's leading producers of renewable, fiber-based packaging, International Paper uses new pulp from sustainably managed forests, and millions of tons of used cardboard, which is processed into new boxes. It is this end-to-end circular model that sets IP's approach apart from almost every other cardboard recycler.

International Paper works at every level of the circular economy to improve recovery and recycling of fiber; it is critical to its entire business. IP makes about one of every three cardboard boxes used in the United States, and on average, a third of the fiber in any given box is recycled. As such, International Paper is one of the largest buyers of used cardboard globally. The company recovers, processes, buys or facilitates the sale of more than 7 million tons of fiber every year. That is 12% of the entire U.S. market for recycled cardboard. And IP has increased recovery of OCC by 60% since 2010. That recovery is good for communities nationwide as it reduces the volume of materials sent to landfill and extends the useful life of natural resources.

The current rate of recovered fiber is high: nearing 70% in the United States and Europe, and 80% in Japan, this number approaches what the World Business Council for Sustainable Development (WBCSD) estimates to be the "maximum that can be practically achieved".24 An estimated 10 tons of recovered bulk cardboard yields approximately 8 tons of reusable pulp. While that is a high ratio, it will likely never be 100%. If the industry had to rely solely on recovered fiber, it could run out of raw material entirely within six months. Additionally, recovered fiber can only produce "new paper of an equal or lower grade," meaning new fiber is necessary to retain a high level of quality. This is why International Paper uses both responsibly grown and managed new fiber along with recycled fiber to make sustainable, fiber-based products.

Learn how International Paper applies circularity principles to the manufacturing of it's sustainable packaging products in their white paper 'Thinking Inside the Box.

About International Paper

International Paper (NYSE:IP) is a global producer of sustainable packaging, pulp and other fiber-based products, and one of the world's largest recyclers. Headquartered in Memphis, Tenn., we employ approximately 39,000 colleagues globally who are committed to creating what's next. We serve customers worldwide, with manufacturing operations in North America, Latin America, North Africa and Europe. Net sales for 2023 were $18.9 billion. Additional information can be found by visiting internationalpaper.com.

About International Paper - EMEA

In Europe, Middle East & Africa (EMEA), International Paper focuses on the production and marketing of fiber-based packaging and specialty pulp, employing approximately 4,400 people. As a leading supplier of high-quality corrugated containers for a multitude of applications, we serve customers throughout the region from our network of two recycled containerboard mills and 23 box plants in France, Italy, Morocco, Portugal and Spain. Specialty pulp is made in Gdansk, Poland. Other products available from International Paper in the region include a variety of Kraft linerboard and other pulp products.

View additional multimedia and more ESG storytelling from International Paper Company on 3blmedia.com.

Contact Info:

Spokesperson: International Paper Company

Website: https://www.3blmedia.com/profiles/international-paper-company

Email: info@3blmedia.com

SOURCE: International Paper Company

View the original press release on accesswire.com