DRILLS 7.5 METRES @ 36.2 g/t GOLD

VANCOUVER, BC / ACCESS Newswire / February 18, 2025 / Southern Cross Gold Consolidated Ltd. ("SXGC" or the "Company") (TSXV:SXGC)(ASX:SX2)(OTC PINK:MWSNF)(Frankfurt:MV3.F) is pleased to announce significant new results from drill hole SDDSC120W1, at the Rising Sun and Golden Dyke prospects, part of the 100%-owned Sunday Creek project.

HIGH LEVEL TAKEAWAY

Southern Cross Gold's latest drill hole at Sunday Creek (SDDSC120W1) has delivered outstanding results, headlined by a 7.5 m intersection grading 36.2 g/t gold within a broader 347 m intersection within the mineralized host. The hole intersected six high-grade vein sets, including two previously unknown, with spectacular zones including 1.0 m @ 262.1 g/t AuEq and 0.3 m @ 122.1 g/t AuEq. Notably, the drilling successfully extended known mineralization up to 88 m down-dip on key structures.

The technical execution proved particularly impressive, with the team successfully drilling at an opposing orientation to earlier holes. This new angle provided crucial validation of structural assumptions, with the predicted RS15 vein set intersected with metre-level accuracy. After the parent hole deviated into the footwall, the team's wedge strategy maintained optimal 90 m spacing while testing the target corridor, demonstrating the team's growing understanding of the system, critical factors for resource definition and eventual development.

These results carry heightened strategic significance given the current geopolitical landscape. China's September 2024 announcement of antimony export restrictions has intensified Western nations' search for secure supplies of this critical metal, essential for defense and high-tech applications. Sunday Creek's emergence as one of the Western world's most significant gold-antimony discoveries comes at a crucial time, with its roughly 20% insitu antimony value component providing strategic optionality while the primary gold economics de-risk development.

The project's location in Victoria, Australia, adds another layer of appeal, offering the security of a tier-1 jurisdiction when secure supply chains are increasingly vital. The combination of exceptional grades, growing resource scale, strategic metal exposure, and premier jurisdiction positions Sunday Creek as a uniquely compelling discovery in the current market context.

Michael Hudson, President & CEO of SXGC states: "Large-scale, high-grade deposits in stable jurisdictions are rare global assets. Sunday Creek continues to demonstrate both exceptional grades and significant scale, placing it in an elite category of discoveries.

"The latest results from SDDSC120W1 are particularly significant for two reasons. First, they confirmed grade and structural continuity both up-dip and down-dip. Second, by drilling at an angle opposing our previous orientation but perpendicular to the mineralized structures, we provided crucial validation of our geological model.

"The hole successfully intersected the mineralized host over 347 m, delivering strong grades including 7.5 m at 36.6 g/t AuEq ("gold equivalent') from 731.9 m including 1.0 m at 262.1 g/t AuEq from 734.3 m. Additionally high-grade antimony zones including 0.2 m at 45.5 g/t AuEq with 16.1% antimony were also intercepted.

"Key catalysts over the next quarter include:

An exploration target upgrade is planned to be made in early March 2025.

Expanding the core resource area while conducting monthly internal modelling updates with SRK Consulting to maintain a detailed understanding of the evolving system

Testing regional targets along the 12 km strike length through mapping, geophysics, soil sampling, and one drill rig dedicated to testing these targets.

Stage 2 metallurgical studies are underway and will be reported over the coming quarter.

Five rigs are operational, with a 6 th rig at site that will commence drilling shortly with one rig focussed on regional targets. Two further rigs are being sourced to focus on resource drill out.

Permitting permissions and studies: working closely with the State of Victoria undertaking engineering and environmental studies, including the recent completion of seven water monitoring bores, taking the total to nine on the project, critical for hydrogeological studies."

FOR THOSE WHO LIKE THE DETAILS

HIGHLIGHTS:

SDDSC120W1 successfully intersected 6 high-grade vein sets across a 347 m intersection through the host sequence, delivering exceptional results:

Peak values reached of 464.0 g/t Au and 17.5% Sb. Notable high-grade zones included:

Primary intersection: 7.5 m @ 36.6 g/t AuEq (36.2 g/t Au, 0.2% Sb) from 731.9 m, including:

1.0 m @ 262.1 g/t AuEq (261.5 g/t Au, 0.3% Sb) from 734.3 m

0.4 m @ 33.8 g/t AuEq (Au only) from 773.3 m

1.5 m @ 25.2 g/t AuEq (21.0 g/t Au, 2.2% Sb) from 804.2 m including:

0.3 m @ 122.1 g/t AuEq (103.0 g/t Au, 10.2% Sb)

0.4 m @ 28.0 g/t AuEq (9.2 g/t Au, 10.0% Sb) from 819.4 m, including

0.2 m @ 45.5 g/t AuEq (15.2 g/t Au, 16.1% Sb)

The hole added to Sunday Creek's impressive strike-rate, bringing the total number of high-grade intersections to 56, each exceeding 100 gold-equivalent gram-meters (AuEq g/t x m) from 71.4 km of drilling.

SDDSC120W1 was important as it demonstrated

A clear ability to target gold-antimony mineralization, after the parent hole deviated, allowing the team to redrill and hit high-grade zones within a 348 m corridor while maintaining proper spacing.

Its perpendicular orientation to previous drilling provided crucial validation of structural continuity assumptions and grade continuity, with its main intersection (7.5m @ 36.2 g/t Au) hitting the predicted vein set accurately and showing consistent mineralization with nearby holes.

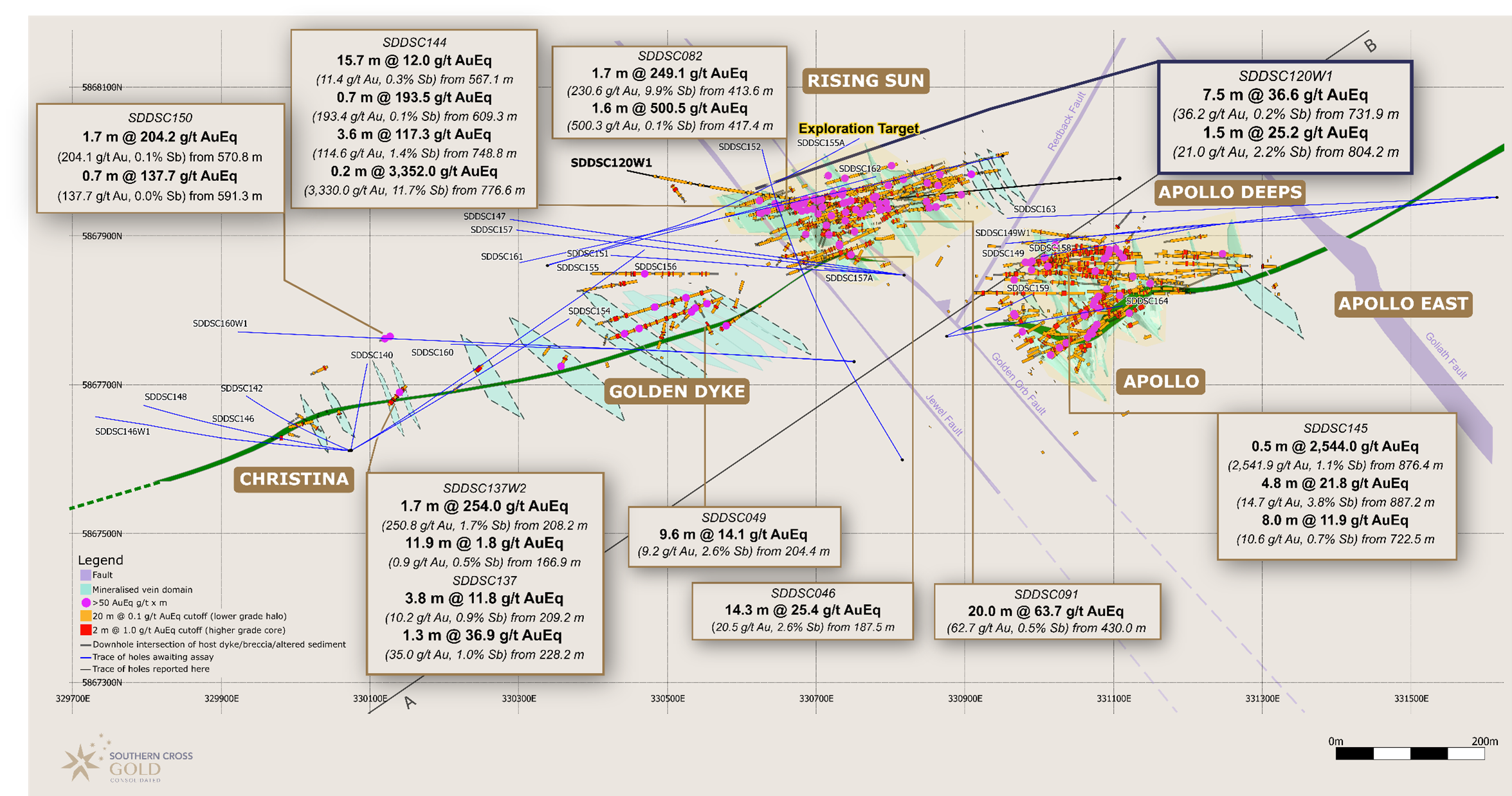

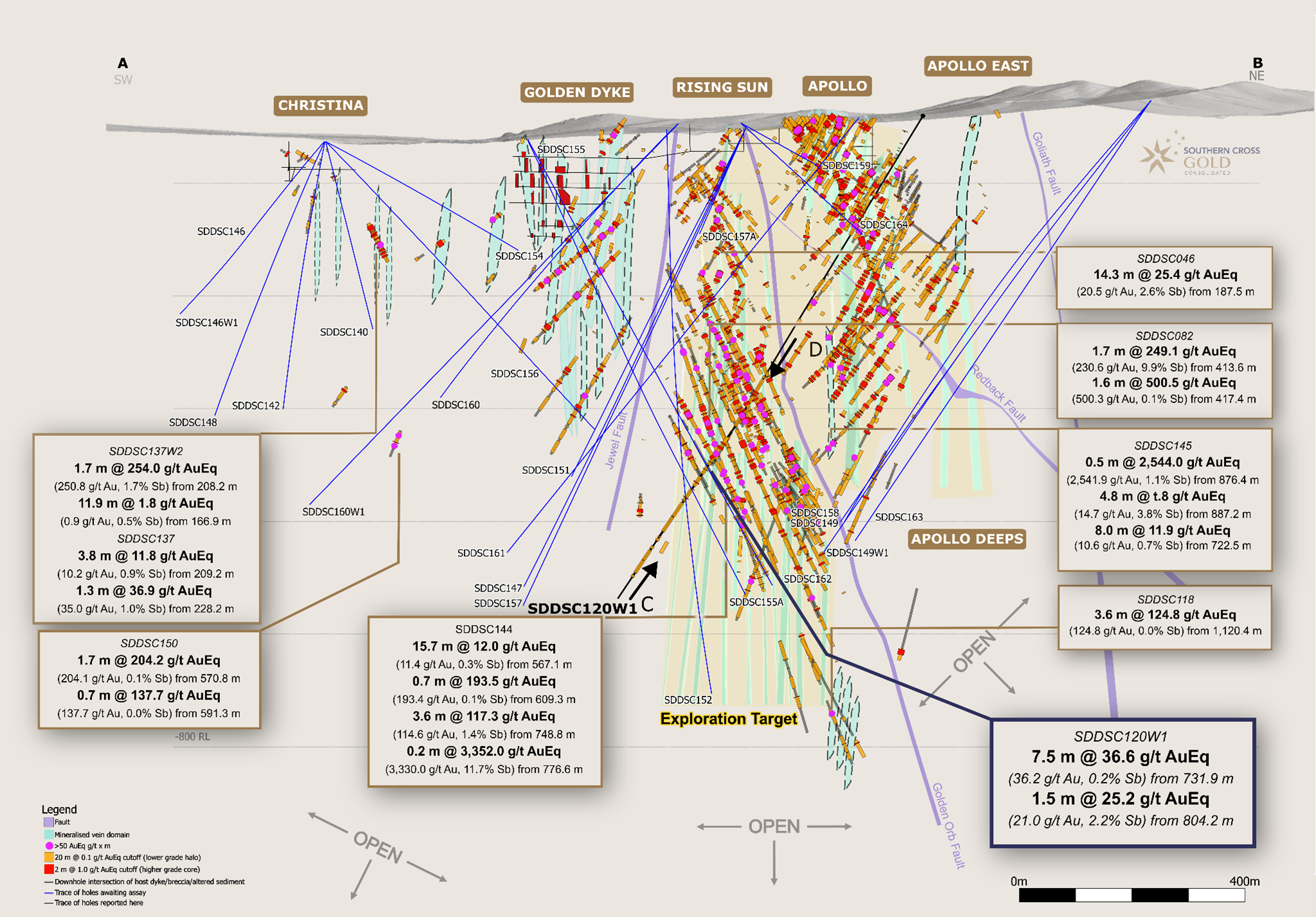

Ongoing Exploration: With $18 million in cash and no debt. Fourteen holes (SDDSC147, 149, 149W1, 151, 152, 154 - 160, 155A, 157A) are currently being processed and analysed, with five holes (SDDSC160W1, 161, 162, 163, 164) in progress (Figure 1 and 2).

Drill Hole Discussion

SDDSC120W1 was drilled east to west as a daughter navigational hole from the parent SDDSC120 ( 23 July, 2024 ) with the intention of targeting the northern strike extent of several vein sets within the western portion of the Rising Sun prospect. The drill hole successfully tested a prospective corridor of 347 m @ 1.2 g.t Au (uncut) (ie the cumulative downhole length of dyke/breccia/altered sediment between the "rails of the ladder") and intercepted six mineralized vein sets , two of which were previously unknown (the "rungs of the ladder"). The hole contained six intervals >20 g/t Au (up to 464.0 g/t Au) and five intervals of >2% Sb (up to 17.5% Sb) . The hole intersected three modelled vein sets, and defined three additional previously unmodelled vein sets one of which lies outside the exploration target area.

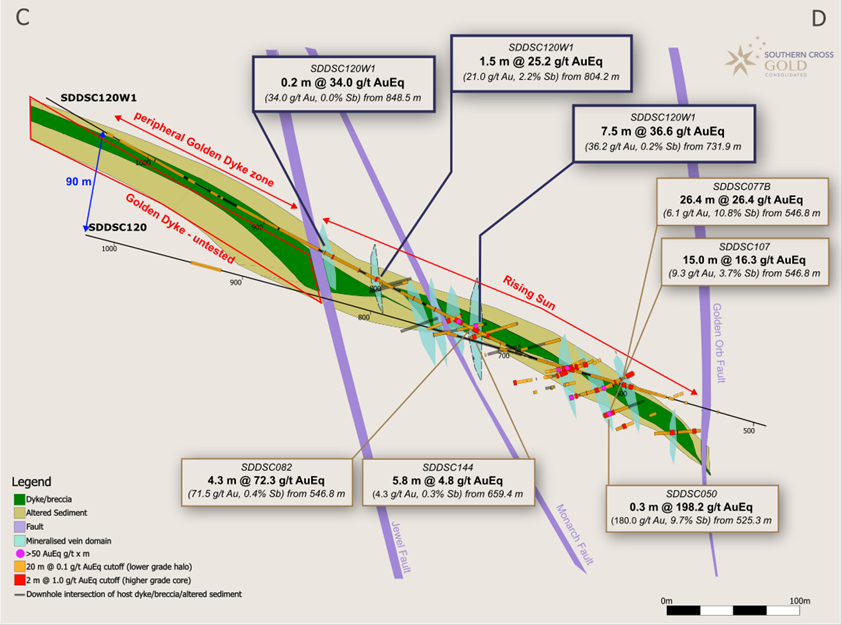

Additionally, 169 m of lower-grade mineralization (0.5 g/t - 5.0 g/t AuEq) was recorded from 861 m downhole, with 137 m of this extending beyond the January 2024 Exploration Target boundary, interpreted as peripheral hanging wall Golden Dyke mineralization (Figure 3).

SDDSC120 was strategically important as it confirms a robust mineralized system at depth, indicates potential for further extensions beyond current model, and contributed to the growing number of high-grade intercepts (now 56 intersections >100 AuEq g/t x metres). The hole demonstrated:

A clear ability to target gold-antimony mineralization , with the parent hole SDDSC120 initially deviating outside the bounds of the mineralized package (the rails of the ladder) into the unmineralized footwall. This allowed the SXGC technical team to wedge and redrill to successfully target high-grade mineralization within a 348m corridor of the mineralized sequence in Rising Sun and Golden Dyke while maintaining a 90m spacing from SDDSC120 over 285m.

SDDSC120W1 was drilled at an opposing orientation (east to west rather than west to east) to earlier drilling that provided an important test of structural continuity and orientation with this alternate drill orientation. This was an important test to validate assumptions and is critical when evaluating any mineral deposit.

SDDSC120W1 proved successful in showing continuity of grade and structure . For example, the headline intersection ( 7.5 m @ 36.2 g/t Au from 731.9 m), intersected the vein set RS15 as predicted with metre accuracy and showed excellent continuity of width and grades of gold. This intersection was located 18 m down-dip in the same vein set in drillhole SDDSC082 (which returned 4.3 metres at 71.5 g/t Au from 590.4 m) and 8 metres up-dip and 5 metres along strike from SDDSC144 (which returned 5.8 metres at 4.3 g/t Au from 659.4 m) (Figure 3).

SDDSC120W1 was planned due to the parent hole (SDDSC120) having deviated into the footwall, missing the full extent of the target system. SDDSC120W1 was drilled at a 90 m spacing from SDDSC120 to ensure coverage of the targeted mineralized corridor. Additionally, the hole provided valuable down-dip extensions to known structures, including RS10 (extended 21 m), RS07 (extended 50 m), and RS06 (extended 88 m).

Extended highlights include:

2.2 m @ 1.6 g/t AuEq (0.6 g/t Au, 0.5% Sb) from 709.6 m

6.2 m @ 1.3 g/t AuEq (0.8 g/t Au, 0.3% Sb) from 716.9 m

7.5 m @ 36.6 g/t AuEq (36.2 g/t Au, 0.2% Sb) from 731.9 m, including:

1.0 m @ 262.1 g/t AuEq (261.5 g/t Au, 0.3% Sb) from 734.3 m

0.3 m @ 8.5 g/t AuEq (8.3 g/t Au, 0.1% Sb) from 745.7 m

0.7 m @ 4.5 g/t AuEq (3.7 g/t Au, 0.4% Sb) from 749.2 m

0.6 m @ 14.4 g/t AuEq (14.1 g/t Au, 0.2% Sb) from 755.1 m, including:

0.1 m @ 71.0 g/t AuEq (69.9 g/t Au, 0.6% Sb) from 755.1 m

0.2 m @ 11.1 g/t AuEq (11.1 g/t Au, 0.0% Sb) from 762.6 m

0.4 m @ 33.8 g/t AuEq (33.8 g/t Au, 0.0% Sb) from 773.3 m

0.2 m @ 15.1 g/t AuEq (15.1 g/t Au, 0.0% Sb) from 776.2 m

1.5 m @ 25.2 g/t AuEq (21.0 g/t Au, 2.2% Sb) from 804.2 m, including:

0.3 m @ 122.1 g/t AuEq (103.0 g/t Au, 10.2% Sb) from 804.8 m

0.4 m @ 28.0 g/t AuEq (9.2 g/t Au, 10.0% Sb) from 819.4 m, including:

0.2 m @ 45.5 g/t AuEq (15.2 g/t Au, 16.1% Sb) from 819.5 m

0.3 m @ 14.4 g/t AuEq (14.4 g/t Au, 0.0% Sb) from 826.3 m

1.1 m @ 5.0 g/t AuEq (5.0 g/t Au, 0.0% Sb) from 841.2 m

0.2 m @ 34.0 g/t AuEq (34.0 g/t Au, 0.0% Sb) from 848.5 m

1.2 m @ 2.3 g/t AuEq (2.2 g/t Au, 0.0% Sb) from 893.3 m

Pending Results and Update

Fourteen holes (SDDSC147, 149, 149W1, 151, 152, 154 - 160, 155A, 157A) are currently being processed and analysed, with five holes (SDDSC160W1, 161, 162, 163, 164) in progress (Figure 1 and 2).

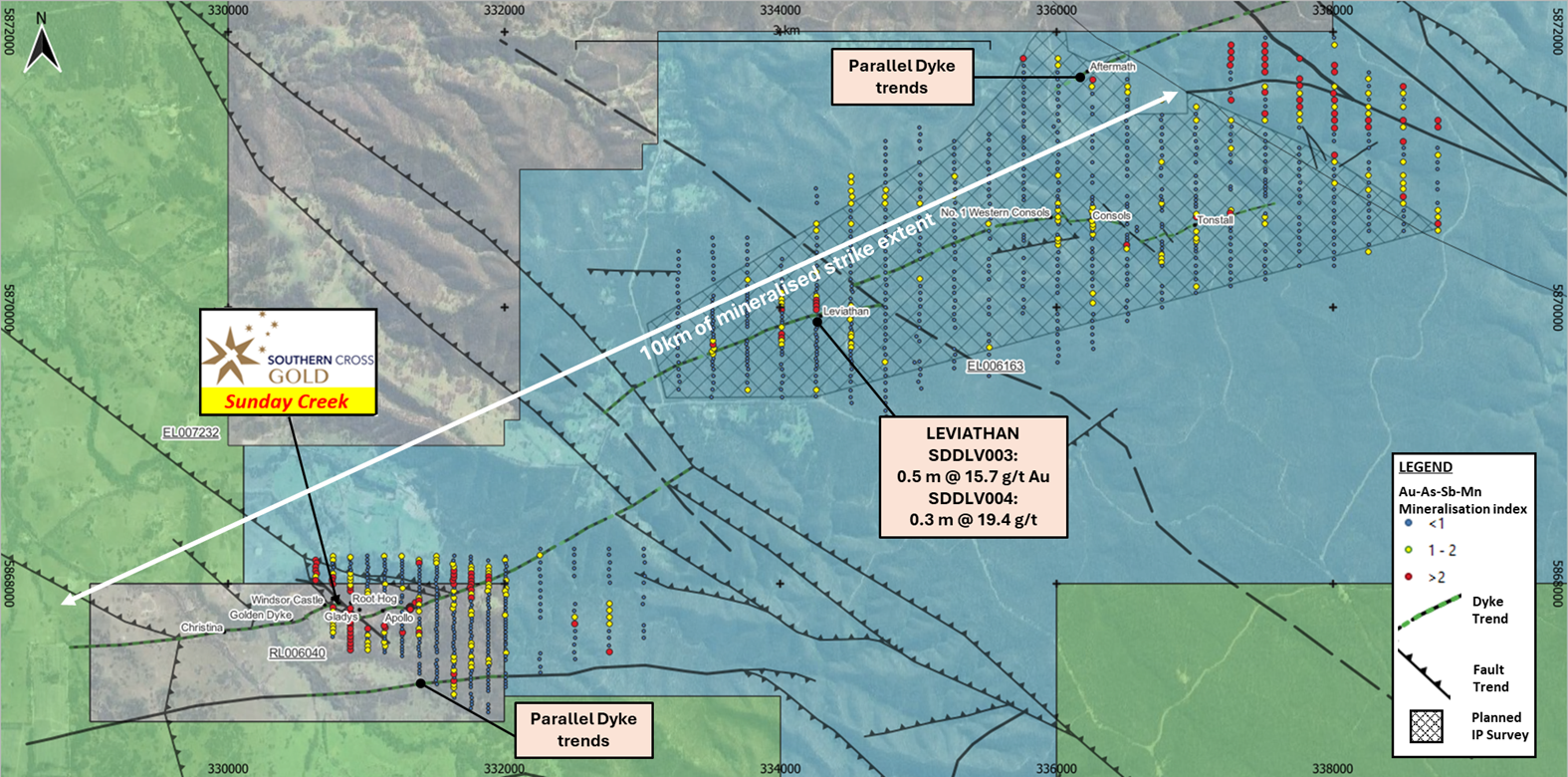

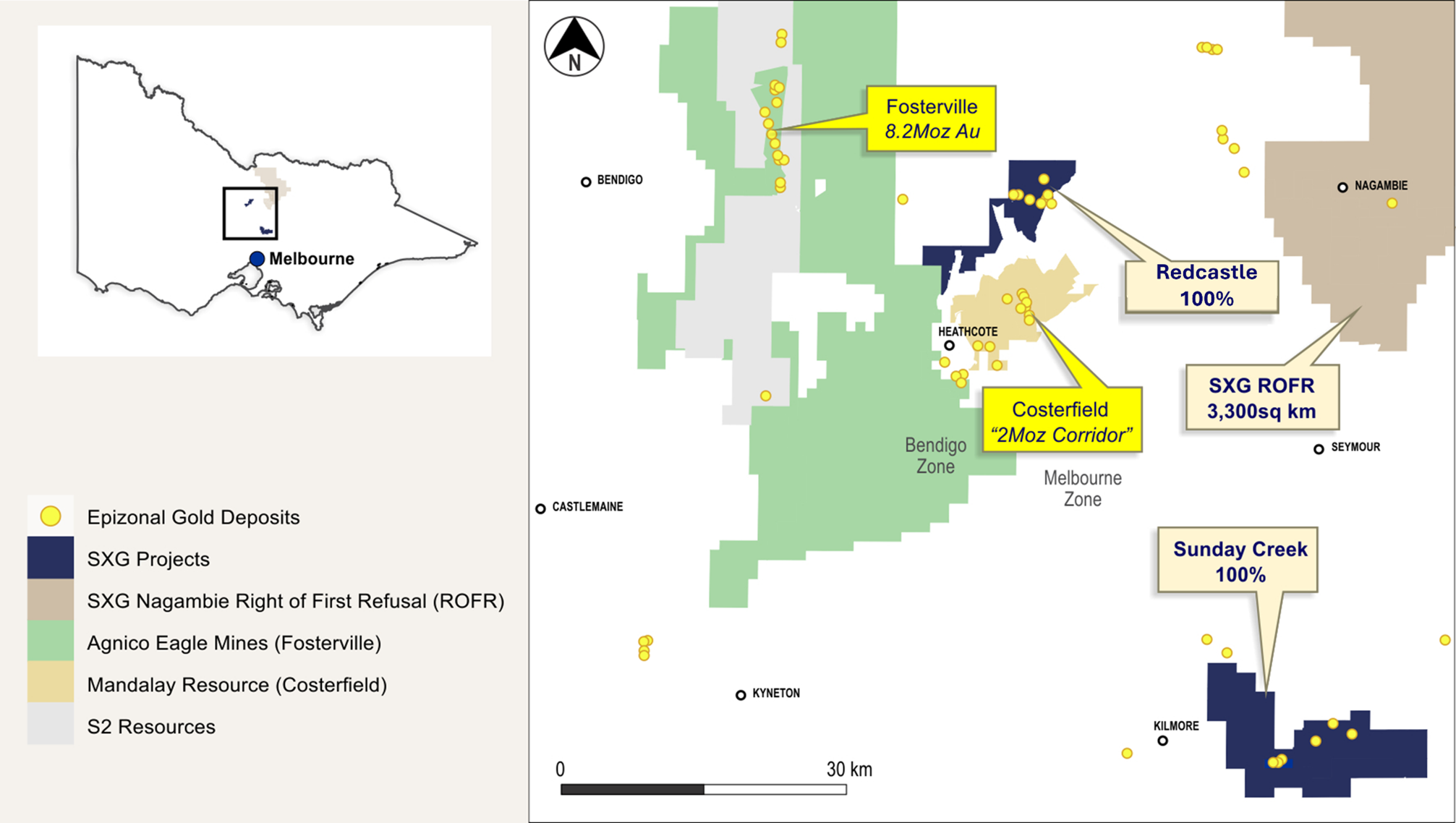

About Sunday Creek

The Sunday Creek epizonal-style gold project (Figure 5) is located 60 km north of Melbourne within 16,900 hectares ("Ha") of granted exploration tenements. SXGC is also the freehold landholder of 1,054.51 Ha that forms the key portion in and around the main drilled area at the Sunday Creek Project.

Gold and antimony form in a relay of vein sets that cut across a steeply dipping zone of intensely altered rocks (the "host"). These vein sets are like a "Golden Ladder" structure where the main host extends between the side rails deep into the earth, with multiple cross-cutting vein sets that host the gold forming the rungs. At Apollo and Rising Sun these individual 'rungs' have been defined over 600 m depth extent from surface to over 1,100 m below surface, are 2.5 m to 3.5 m wide (median widths) (and up to 10 m), and 20 m to 100 m in strike.

Cumulatively, 157 drill holes for 71,400.09 m have been reported from Sunday Creek since late 2020. An additional 12 holes for 582.55 m from Sunday Creek were abandoned due to deviation or hole conditions. Fourteen drillholes for 2,383 m have been reported regionally outside of the main Sunday Creek drill area. A total of 64 historic drill holes for 5,599 m were completed from the late 1960s to 2008. The project now contains a total of fifty-six (56) >100 g/t AuEq x m and sixty (60) >50 to 100 g/t AuEq x m drill holes by applying a 2 m @ 1 g/t AuEq lower cut.

Our systematic drill program is strategically targeting these significant vein formations, initially these have been defined over 1,350 m strike of the host from Christina to Apollo prospects, of which approximately 620 m has been more intensively drill tested (Rising Sun to Apollo). At least 70 'rungs' have been defined to date, defined by high-grade intercepts (20 g/t to >7,330 g/t Au) along with lower grade edges. Ongoing step-out drilling is aiming to uncover the potential extent of this mineralized system (Figure 3).

Geologically, the project is located within the Melbourne Structural Zone in the Lachlan Fold Belt. The regional host to the Sunday Creek mineralization is an interbedded turbidite sequence of siltstones and minor sandstones metamorphosed to sub-greenschist facies and folded into a set of open north-west trending folds.

Further Information

Further discussion and analysis of the Sunday Creek project is available through the interactive Vrify 3D animations, presentations and videos all available on the SXGC website. These data, along with an interview on these results with President & CEO Michael Hudson can be viewed at www.southerncrossgold.com

No upper gold grade cut is applied in the averaging and intervals are reported as drill thickness. However, during future Mineral Resource studies, the requirement for assay top cutting will be assessed. The Company notes that due to rounding of assay results to one significant figure, minor variations in calculated composite grades may occur.

Figures 1 to 4 show project location, plan and longitudinal views of drill results reported here and Tables 1 to 3 provide collar and assay data. The true thickness of the mineralized intervals reported is approximately 40% of the sampled thickness for other reported holes. Lower grades were cut at 1.0 g/t AuEq lower cutoff over a maximum width of 2 m with higher grades cut at 5.0 g/t AuEq lower cutoff over a maximum of 1 m width unless specified unless otherwise* specified to demonstrate higher grade assays.

Critical Metal Epizonal Gold-Antimony Deposits

Sunday Creek (Figure 4) is an epizonal gold-antimony deposit formed in the late Devonian (like Fosterville, Costerfield and Redcastle), 60 million years later than mesozonal gold systems formed in Victoria (for example Ballarat and Bendigo). Epizonal deposits are a form of orogenic gold deposit classified according to their depth of formation: epizonal (<6 km), mesozonal (6-12 km) and hypozonal (>12 km).

Epizonal deposits in Victoria often have associated high levels of the critical metal, antimony, and Sunday Creek is no exception. China claims a 56 per cent share of global mined supplies of antimony, according to a 2023 European Union study. Antimony features highly on the critical minerals lists of many countries including Australia, the United States of America, Canada, Japan and the European Union. Australia ranks seventh for antimony production despite all production coming from a single mine at Costerfield in Victoria, located nearby to all SXGC projects. Antimony alloys with lead and tin which results in improved properties for solders, munitions, bearings and batteries. Antimony is a prominent additive for halogen-containing flame retardants. Adequate supplies of antimony are critical to the world's energy transition, and to the high-tech industry, especially the semi-conductor and defence sectors where it is a critical additive to primers in munitions.

In August 2024, the Chinese government announced it will place export limits from September 15, 2024 on antimony and antimony products. This puts pressure on Western defence supply chains and negatively affect the supply of the metal and push up pricing given China's dominance of the supply of the metal in the global markets. This is positive for SXGC as we are likely to have one of the very few large and high-quality projects of antimony in the western world that can feed western demand into the future.

Antimony represents approximately 20% in situ recoverable value of Sunday Creek at an AuEq of 1.88.

About Southern Cross Gold Consolidated Ltd. (TSXV:SXGC)(ASX:SX2)

Southern Cross Gold Consolidated Ltd is now dual listed on the TSXV:SXGC and ASX:SX2

Southern Cross Gold Consolidated Ltd. (TSXV:SXGC, ASX:SX2) controls the Sunday Creek Gold-Antimony Project located 60 kilometres north of Melbourne, Australia. Sunday Creek has emerged as one of the Western world's most significant gold and antimony discoveries, with exceptional drilling results including 55 intersections exceeding 100 g/t AuEq x m from just 70.7 km of drilling. The mineralization follows a "Golden Ladder" structure over 12 km of strike length, with confirmed continuity from surface to 1,100 m depth.

Sunday Creek's strategic value is enhanced by its dual-metal profile, with antimony contributing 20% of the in-situ value alongside gold. This has gained increased significance following China's export restrictions on antimony, a critical metal for defense and semiconductor applications. Southern Cross' inclusion in the US Defense Industrial Base Consortium (DIBC) and Australia's AUKUS-related legislative changes position it as a potential key Western antimony supplier. Importantly, Sunday Creek can be developed primarily based on gold economics, which reduces antimony-related risks while maintaining strategic supply potential.

Technical fundamentals further strengthen the investment case, with preliminary metallurgical work showing non-refractory mineralization suitable for conventional processing and gold recoveries of 93-98% through gravity and flotation.

With A$18M in cash, over 1,000 Ha of strategic freehold land ownership, and an aggressive 60 km drill program planned through Q3 2025, SXGC is well-positioned to advance this globally significant gold-antimony discovery in a tier-one jurisdiction.

NI 43-101 Technical Background and Qualified Person

Michael Hudson, President and CEO and Managing Director of SXGC, and a Fellow of the Australasian Institute of Mining and Metallurgy, and Mr Kenneth Bush, Exploration Manager of SXGC and a Member of Australian Institute of Geoscientists, are the Qualified Persons as defined by the NI 43-101. They have reviewed, verified and approved the technical contents of this release.

Analytical samples are transported to the Bendigo facility of On Site Laboratory Services ("On Site") which operates under both an ISO 9001 and NATA quality systems. Samples were prepared and analyzed for gold using the fire assay technique (PE01S method; 25 g charge), followed by measuring the gold in solution with flame AAS equipment. Samples for multi-element analysis (BM011 and over-range methods as required) use aqua regia digestion and ICP-MS analysis. The QA/QC program of Southern Cross Gold consists of the systematic insertion of certified standards of known gold and antimony content, blanks within interpreted mineralized rock and quarter core duplicates. In addition, On Site inserts blanks and standards into the analytical process.

SXGC considers that both gold and antimony that are included in the gold equivalent calculation ("AuEq") have reasonable potential to be recovered at Sunday Creek, given current geochemical understanding, historic production statistics and geologically analogous mining operations. Historically, ore from Sunday Creek was treated onsite or shipped to the Costerfield mine, located 54 km to the northwest of the project, for processing during WW1. The Costerfield mine corridor, now owned by Mandalay Resources Ltd contains two million ounces of equivalent gold (Mandalay Q3 2021 Results), and in 2020 was the sixth highest-grade global underground mine and a top 5 global producer of antimony.

SXGC considers that it is appropriate to adopt the same gold equivalent variables as Mandalay Resources Ltd in its Mandalay Technical Report, 2024 dated March 28, 2024. The gold equivalence formula used by Mandalay Resources was calculated using Costerfield's 2023 production costs, using a gold price of US$1,900 per ounce, an antimony price of US$12,000 per tonne and 2023 total year metal recoveries of 94% for gold and 89% for antimony, and is as follows:

???????? = ???? (??/??) + 1.88 × ???? (%).

Based on the latest Costerfield calculation and given the similar geological styles and historic toll treatment of Sunday Creek mineralization at Costerfield, SXGC considers that a ???????? = ???? (??/??) + 1.88 × ???? (%) is appropriate to use for the initial exploration targeting of gold-antimony mineralization at Sunday Creek.

JORC Competent Person Statement

Information in this announcement that relates to new exploration results contained in this report is based on information compiled by Mr Kenneth Bush and Mr Michael Hudson. Mr Bush is a Member of Australian Institute of Geoscientists and a Registered Professional Geologist and Member of the Australasian Institute of Mining and Metallurgy and Mr Hudson is a Fellow of The Australasian Institute of Mining and Metallurgy. Mr Bush and Mr Hudson each have sufficient experience relevant to the style of mineralization and type of deposit under consideration, and to the activities undertaken, to qualify as a Competent Person as defined in the 2012 Edition of the Joint Ore Reserves Committee (JORC) Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves. Mr Bush is Exploration Manager and Mr Hudson is Managing Director of Southern Cross Gold Limited and both consent to the inclusion in the report of the matters based on their information in the form and context in which it appears.

Certain information in this announcement that relates to prior exploration results is extracted from the Independent Geologist's Report dated 11 December 2024 which was issued with the consent of the Competent Person, Mr Steven Tambanis. The report is included the Company's prospectus dated 11 December 2024 and is available at www2.asx.com.au under code "SXGC". The Company confirms that it is not aware of any new information or data that materially affects the information related to exploration results included in the original market announcement. The Company confirms that the form and context of the Competent Persons' findings in relation to the report have not been materially modified from the original market announcement.

The Company confirms that it is not aware of any new information or data that materially affects the information included in the original document/announcement and the Company confirms that the form and context in which the Competent Person's findings are presented have not materially modified from the original market announcement.

- Ends -

This announcement has been approved for release by the Board of Southern Cross Gold Consolidated Ltd.

For further information, please contact:

Mariana Bermudez - Corporate Secretary - Canada

mbermudez@chasemgt.com or +1 604 685 9316

Executive Office: 1305 - 1090 West Georgia Street Vancouver, BC, V6E 3V7, Canada

Nicholas Mead - Corporate Development

info@southerncrossgold.com or +61 415 153 122

Justin Mouchacca, Company Secretary - Australia

jm@southerncrossgold.com.au or +61 3 8630 3321

Subsidiary Office: Level 21, 459 Collins Street, Melbourne, VIC, 3000, Australia

Forward-Looking Statement

This news release contains forward-looking statements. Forward-looking statements involve known and unknown risks, uncertainties and assumptions and accordingly, actual results and future events could differ materially from those expressed or implied in such statements. You are hence cautioned not to place undue reliance on forward-looking statements. All statements other than statements of present or historical fact are forward-looking statements including without limitation applicable court, regulatory authorities and applicable stock exchanges. Forward-looking statements include words or expressions such as "proposed", "will", "subject to", "near future", "in the event", "would", "expect", "prepared to" and other similar words or expressions. Factors that could cause future results or events to differ materially from current expectations expressed or implied by the forward-looking statements include general business, economic, competitive, political, social uncertainties; the state of capital markets, unforeseen events, developments, or factors causing any of the expectations, assumptions, and other factors ultimately being inaccurate or irrelevant; and other risks described in SXGC's documents filed with Canadian or Australian securities regulatory authorities (under code SX2). You can find further information with respect to these and other risks in filings made by SXGC with the securities regulatory authorities in Canada or Australia (under code SX2), as applicable, and available for SXGC in Canada at www.sedarplus.ca or in Australia at www2.asx.com.au under code SX2. Documents are also available at www.southerncrossgold.com We disclaim any obligation to update or revise these forward-looking statements, except as required by applicable law.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) or the Australian Securities Exchange accepts responsibility for the adequacy or accuracy of this release.

Figure 1: Sunday Creek plan view showing selected results from holes SDDSC120W1 reported here (black highlighted box, black trace), with selected prior reported drill holes and pending holes.

Figure 2: Sunday Creek longitudinal section across A-B in the plane of the dyke breccia/altered sediment host looking towards the north (striking 236 degrees) showing mineralized veins sets. Showing holes SDDSC120W1 reported here (black highlighted box, black trace), with selected intersections and prior reported drill holes. The vertical extents of the vein sets are limited by proximity to drill hole pierce points. For location refer to Figure 1.

Figure 3: Inclined plan section (25 m influence - looking down) along C-D, parallel to reported hole SDDSC120W1 and its parent drill hole SDDSC120, showing geology model (green, yellow and purple polygons) and mineralized domains (blue polygons). Section shows 50 m thick slice.

Figure 4: Sunday Creek regional plan view showing soil sampling, structural framework, regional historic epizonal gold mining areas and broad regional areas tested by 12 holes for 2,383 m drill program. The regional drill areas are at Tonstal, Consols and Leviathan located 4,000-7,500 m along strike from the main drill area at Golden Dyke- Apollo.

Figure 5: Location of the Sunday Creek project, along with the 100% owned Redcastle Gold-Antimony Project

Table 1: Drill collar summary table for recent drill holes in progress.

Hole-ID | Depth (m) | Prospect | East GDA94_Z55 | North GDA94_Z55 | Elevation | Azimuth | Plunge |

SDDSC140 | 352.9 | Christina | 330075 | 5867612 | 274 | 9 | -70 |

SDDSC142 | 500.67 | Christina | 330075 | 5867612 | 274 | 292 | -70 |

SDDSC146 | 245.7 | Christina | 330073 | 5867612 | 274 | 273 | -42 |

SDDSC146W1 | 461.2 | Christina | 330073 | 5867612 | 274 | 273 | -42 |

SDDSC147 | 977.15 | Golden Dyke | 330809 | 5867842 | 301 | 278 | -57 |

SDDSC148 | 563.6 | Christina | 330073 | 5867611 | 274 | 278 | -57.2 |

SDDSC149 | 970.79 | Apollo | 331594 | 5867955 | 344 | 266 | -47 |

SDDSC149W1 | 1041.1 | Apollo | 331594 | 5867955 | 344 | 266 | -47 |

SDDSC150 | 638.8 | Christina | 330340 | 5867865 | 277 | 244 | -65 |

SDDSC151 | 737.2 | Golden Dyke | 330818 | 5867847 | 301 | 273.8 | -56.5 |

SDDSC152 | 1102.7 | Rising Sun | 330816 | 5867599 | 296 | 328 | -65 |

SDDSC153 | 639.1 | Christina | 330333 | 5867860 | 277 | 244.8 | -52.5 |

SDDSC154 | 392.9 | Christina | 330075 | 5867612 | 274 | 60 | -26.5 |

SDDSC155 | 31 | Rising Sun | 330339 | 5867860 | 277 | 72.7 | -63.5 |

SDDSC155A | 896.4 | Rising Sun | 330339 | 5867860 | 277 | 72.7 | -63.5 |

SDDSC156 | 755.55 | Christina | 330075 | 5867612 | 274 | 59.5 | -45.3 |

SDDSC157 | 1115.7 | Golden Dyke | 330318 | 5867847 | 301 | 276.6 | -58.4 |

SDDSC157A | 219.9 | Golden Dyke | 330318 | 5867847 | 301 | 276.2 | -60 |

SDDSC158 | 992.5 | Apollo | 331616 | 5867952 | 347 | 265.5 | -45 |

SDDSC159 | 145.2 | Gladys | 330871 | 5867758 | 308 | 60.5 | -28.9 |

SDDSC160 | 725.1 | Christina | 330753 | 5867733 | 307 | 272.5 | -37.8 |

SDDSC161 | In progress plan 1020 m | Golden Dyke | 330951 | 5868007 | 314 | 257 | -49.4 |

SDDSC162 | In progress plan 920 m | Rising Sun | 330339 | 5867864 | 277 | 75.4 | -59.6 |

SDDSC163 | In progress plan 1000 m | Apollo | 331615.5 | 5867952 | 347 | 267.2 | -48.5 |

SDDSC164 | In progress plan 315 m | Gladys | 330871 | 5867758 | 308 | 78.2 | -40 |

SDDSC160W1 | In progress plan 1070 m | Christina | 330753 | 5867731 | 307 | 272.5 | -37.8 |

Table 2: Table of mineralized drill hole intersections reported from SDDSC120W1 using two cutoff criteria. Lower grades cut at 1.0 g/t AuEq lower cutoff over a maximum of 2 m with higher grades cut at 5.0 g/t AuEq cutoff over a maximum of 1 m.

Hole-ID | From (m) | To (m) | Length (m) | Au (g/t) | Sb (%) | AuEq (g/t) |

SDDSC120W1 | 709.6 | 711.8 | 2.2 | 0.6 | 0.5 | 1.6 |

SDDSC120W1 | 716.9 | 723.1 | 6.2 | 0.8 | 0.3 | 1.3 |

SDDSC120W1 | 731.9 | 739.4 | 7.5 | 36.2 | 0.2 | 36.6 |

Including | 734.3 | 735.3 | 1.0 | 261.5 | 0.3 | 262.1 |

SDDSC120W1 | 745.7 | 746.0 | 0.3 | 8.3 | 0.1 | 8.5 |

SDDSC120W1 | 749.2 | 749.9 | 0.7 | 3.7 | 0.4 | 4.5 |

SDDSC120W1 | 755.1 | 755.7 | 0.6 | 14.1 | 0.2 | 14.4 |

Including | 755.1 | 755.2 | 0.1 | 69.9 | 0.6 | 71.0 |

SDDSC120W1 | 762.6 | 762.8 | 0.2 | 11.1 | 0.0 | 11.1 |

SDDSC120W1 | 773.3 | 773.7 | 0.4 | 33.8 | 0.0 | 33.8 |

SDDSC120W1 | 776.2 | 776.4 | 0.2 | 15.1 | 0.0 | 15.1 |

SDDSC120W1 | 804.2 | 805.7 | 1.5 | 21.0 | 2.2 | 25.2 |

Including | 804.8 | 805.1 | 0.3 | 103.0 | 10.2 | 122.1 |

SDDSC120W1 | 819.4 | 819.8 | 0.4 | 9.2 | 10.0 | 28.0 |

Including | 819.5 | 819.7 | 0.2 | 15.2 | 16.1 | 45.5 |

SDDSC120W1 | 826.3 | 826.6 | 0.3 | 14.4 | 0.0 | 14.4 |

SDDSC120W1 | 841.2 | 842.3 | 1.1 | 5.0 | 0.0 | 5.0 |

SDDSC120W1 | 848.5 | 848.7 | 0.2 | 34.0 | 0.0 | 34.0 |

SDDSC120W1 | 893.3 | 894.5 | 1.2 | 2.2 | 0.0 | 2.3 |

Table 3: All individual assays reported from SDDSC120W1 reported here >0.1g/t AuEq.

Hole-ID | From (m) | To (m) | Length (m) | Au (g/t) | Sb (%) | AuEq (g/t) |

SDDSC120W1 | 695.7 | 697.0 | 1.3 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 698.3 | 699.6 | 1.3 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 700.8 | 701.2 | 0.4 | 0.3 | 0.5 | 1.1 |

SDDSC120W1 | 701.2 | 701.9 | 0.7 | 0.0 | 0.0 | 0.1 |

SDDSC120W1 | 701.9 | 702.2 | 0.3 | 0.9 | 0.1 | 1.1 |

SDDSC120W1 | 702.2 | 703.5 | 1.3 | 0.1 | 0.1 | 0.2 |

SDDSC120W1 | 704.5 | 705.2 | 0.7 | 0.1 | 0.1 | 0.4 |

SDDSC120W1 | 705.2 | 705.7 | 0.5 | 0.1 | 0.1 | 0.4 |

SDDSC120W1 | 705.7 | 706.1 | 0.4 | 0.3 | 0.6 | 1.4 |

SDDSC120W1 | 706.1 | 706.5 | 0.4 | 0.3 | 0.2 | 0.7 |

SDDSC120W1 | 706.5 | 707.2 | 0.7 | 0.3 | 0.2 | 0.6 |

SDDSC120W1 | 707.2 | 708.0 | 0.8 | 0.3 | 0.1 | 0.5 |

SDDSC120W1 | 708.0 | 708.7 | 0.7 | 0.4 | 0.1 | 0.5 |

SDDSC120W1 | 708.7 | 709.6 | 0.9 | 0.4 | 0.1 | 0.7 |

SDDSC120W1 | 709.6 | 710.0 | 0.4 | 0.2 | 1.9 | 3.8 |

SDDSC120W1 | 710.0 | 710.7 | 0.7 | 1.0 | 0.2 | 1.4 |

SDDSC120W1 | 710.7 | 711.6 | 1.0 | 0.2 | 0.1 | 0.3 |

SDDSC120W1 | 711.6 | 711.8 | 0.2 | 2.9 | 1.1 | 4.9 |

SDDSC120W1 | 711.8 | 712.6 | 0.9 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 712.6 | 713.1 | 0.5 | 0.4 | 0.0 | 0.4 |

SDDSC120W1 | 713.1 | 713.8 | 0.7 | 0.5 | 0.1 | 0.7 |

SDDSC120W1 | 713.8 | 715.0 | 1.2 | 0.5 | 0.0 | 0.5 |

SDDSC120W1 | 716.9 | 717.0 | 0.1 | 3.2 | 0.6 | 4.4 |

SDDSC120W1 | 717.0 | 717.6 | 0.6 | 0.7 | 0.1 | 0.9 |

SDDSC120W1 | 717.6 | 718.6 | 1.0 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 718.6 | 718.8 | 0.2 | 0.7 | 0.2 | 1.1 |

SDDSC120W1 | 718.8 | 719.7 | 0.9 | 0.1 | 0.0 | 0.2 |

SDDSC120W1 | 719.7 | 719.8 | 0.1 | 12.5 | 1.3 | 15.0 |

SDDSC120W1 | 719.8 | 720.4 | 0.7 | 0.1 | 0.1 | 0.2 |

SDDSC120W1 | 720.4 | 720.7 | 0.3 | 5.1 | 0.6 | 6.1 |

SDDSC120W1 | 720.7 | 720.9 | 0.2 | 2.1 | 0.4 | 2.8 |

SDDSC120W1 | 720.9 | 721.4 | 0.5 | 0.5 | 0.1 | 0.7 |

SDDSC120W1 | 721.4 | 721.5 | 0.1 | 0.4 | 0.6 | 1.5 |

SDDSC120W1 | 721.5 | 721.9 | 0.3 | 0.2 | 0.1 | 0.5 |

SDDSC120W1 | 721.9 | 722.0 | 0.2 | 1.4 | 3.3 | 7.6 |

SDDSC120W1 | 722.0 | 723.0 | 1.0 | 0.2 | 0.2 | 0.5 |

SDDSC120W1 | 723.0 | 723.1 | 0.1 | 1.0 | 2.2 | 5.1 |

SDDSC120W1 | 723.1 | 724.1 | 1.0 | 0.2 | 0.1 | 0.3 |

SDDSC120W1 | 724.1 | 724.8 | 0.6 | 0.2 | 0.2 | 0.6 |

SDDSC120W1 | 724.8 | 726.0 | 1.2 | 0.2 | 0.1 | 0.3 |

SDDSC120W1 | 726.0 | 726.6 | 0.6 | 0.5 | 0.5 | 1.5 |

SDDSC120W1 | 726.6 | 727.4 | 0.9 | 0.1 | 0.3 | 0.7 |

SDDSC120W1 | 729.3 | 729.4 | 0.2 | 0.1 | 0.2 | 0.6 |

SDDSC120W1 | 730.9 | 731.9 | 1.0 | 0.1 | 0.0 | 0.2 |

SDDSC120W1 | 731.9 | 732.5 | 0.6 | 3.0 | 0.4 | 3.8 |

SDDSC120W1 | 732.5 | 733.0 | 0.5 | 0.4 | 0.0 | 0.5 |

SDDSC120W1 | 733.0 | 733.7 | 0.7 | 0.3 | 0.0 | 0.3 |

SDDSC120W1 | 733.7 | 734.1 | 0.4 | 0.5 | 0.1 | 0.6 |

SDDSC120W1 | 734.1 | 734.3 | 0.2 | 2.2 | 0.0 | 2.2 |

SDDSC120W1 | 734.3 | 734.7 | 0.3 | 66.3 | 0.6 | 67.3 |

SDDSC120W1 | 734.7 | 734.8 | 0.2 | 2.1 | 0.2 | 2.5 |

SDDSC120W1 | 734.8 | 735.3 | 0.5 | 464.0 | 0.2 | 464.3 |

SDDSC120W1 | 735.3 | 735.7 | 0.4 | 1.8 | 0.2 | 2.1 |

SDDSC120W1 | 735.7 | 736.0 | 0.3 | 0.2 | 0.1 | 0.3 |

SDDSC120W1 | 736.0 | 736.4 | 0.4 | 0.2 | 0.1 | 0.3 |

SDDSC120W1 | 736.4 | 737.0 | 0.6 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 737.0 | 737.1 | 0.2 | 0.8 | 0.7 | 2.1 |

SDDSC120W1 | 737.1 | 738.1 | 1.0 | 0.1 | 0.0 | 0.2 |

SDDSC120W1 | 738.1 | 738.3 | 0.2 | 3.9 | 1.8 | 7.3 |

SDDSC120W1 | 738.3 | 738.8 | 0.5 | 0.6 | 0.6 | 1.8 |

SDDSC120W1 | 738.8 | 739.0 | 0.2 | 0.3 | 0.2 | 0.7 |

SDDSC120W1 | 739.0 | 739.4 | 0.4 | 1.9 | 0.3 | 2.4 |

SDDSC120W1 | 739.4 | 740.5 | 1.2 | 0.5 | 0.1 | 0.7 |

SDDSC120W1 | 740.5 | 741.7 | 1.1 | 0.3 | 0.0 | 0.4 |

SDDSC120W1 | 741.7 | 741.8 | 0.1 | 0.7 | 0.0 | 0.7 |

SDDSC120W1 | 743.1 | 743.8 | 0.7 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 743.8 | 744.3 | 0.5 | 0.5 | 0.1 | 0.7 |

SDDSC120W1 | 745.5 | 745.7 | 0.2 | 0.8 | 0.0 | 0.9 |

SDDSC120W1 | 745.7 | 746.0 | 0.3 | 8.3 | 0.1 | 8.5 |

SDDSC120W1 | 748.0 | 748.4 | 0.4 | 0.4 | 0.1 | 0.5 |

SDDSC120W1 | 748.4 | 749.2 | 0.8 | 0.3 | 0.1 | 0.4 |

SDDSC120W1 | 749.2 | 749.9 | 0.7 | 3.7 | 0.4 | 4.5 |

SDDSC120W1 | 749.9 | 750.7 | 0.9 | 0.7 | 0.1 | 0.8 |

SDDSC120W1 | 750.7 | 751.8 | 1.1 | 0.3 | 0.0 | 0.3 |

SDDSC120W1 | 751.8 | 752.6 | 0.8 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 754.0 | 754.8 | 0.8 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 754.8 | 755.1 | 0.2 | 0.8 | 0.0 | 0.8 |

SDDSC120W1 | 755.1 | 755.2 | 0.1 | 69.9 | 0.6 | 71.1 |

SDDSC120W1 | 755.2 | 755.7 | 0.5 | 1.0 | 0.1 | 1.1 |

SDDSC120W1 | 755.7 | 756.6 | 0.9 | 0.1 | 0.0 | 0.2 |

SDDSC120W1 | 757.5 | 758.5 | 1.0 | 0.3 | 0.0 | 0.3 |

SDDSC120W1 | 759.6 | 760.2 | 0.6 | 0.5 | 0.0 | 0.5 |

SDDSC120W1 | 762.0 | 762.6 | 0.6 | 0.5 | 0.0 | 0.6 |

SDDSC120W1 | 762.6 | 762.8 | 0.2 | 11.1 | 0.0 | 11.1 |

SDDSC120W1 | 766.2 | 766.3 | 0.2 | 0.6 | 0.0 | 0.6 |

SDDSC120W1 | 766.3 | 766.6 | 0.3 | 1.5 | 0.0 | 1.6 |

SDDSC120W1 | 773.3 | 773.7 | 0.4 | 33.8 | 0.0 | 33.8 |

SDDSC120W1 | 773.7 | 773.9 | 0.2 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 776.2 | 776.4 | 0.2 | 15.1 | 0.0 | 15.1 |

SDDSC120W1 | 784.0 | 784.6 | 0.6 | 0.5 | 0.0 | 0.6 |

SDDSC120W1 | 790.6 | 791.0 | 0.3 | 1.4 | 0.0 | 1.5 |

SDDSC120W1 | 796.9 | 797.5 | 0.5 | 0.3 | 0.0 | 0.3 |

SDDSC120W1 | 804.2 | 804.8 | 0.7 | 0.6 | 0.4 | 1.3 |

SDDSC120W1 | 804.8 | 804.9 | 0.1 | 1.3 | 2.3 | 5.6 |

SDDSC120W1 | 804.9 | 805.1 | 0.2 | 198.0 | 17.5 | 230.9 |

SDDSC120W1 | 805.1 | 805.3 | 0.2 | 2.0 | 0.3 | 2.5 |

SDDSC120W1 | 805.3 | 805.4 | 0.1 | 1.5 | 0.6 | 2.6 |

SDDSC120W1 | 805.4 | 805.7 | 0.3 | 3.8 | 0.3 | 4.4 |

SDDSC120W1 | 805.7 | 806.3 | 0.6 | 0.2 | 0.1 | 0.3 |

SDDSC120W1 | 807.1 | 807.8 | 0.6 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 808.5 | 809.2 | 0.7 | 0.3 | 0.0 | 0.3 |

SDDSC120W1 | 809.2 | 810.1 | 0.9 | 0.3 | 0.0 | 0.3 |

SDDSC120W1 | 812.1 | 812.5 | 0.5 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 812.5 | 813.0 | 0.5 | 0.4 | 0.0 | 0.5 |

SDDSC120W1 | 813.0 | 813.9 | 0.9 | 0.5 | 0.1 | 0.6 |

SDDSC120W1 | 819.2 | 819.4 | 0.1 | 0.5 | 0.1 | 0.6 |

SDDSC120W1 | 819.4 | 819.5 | 0.2 | 0.7 | 1.2 | 2.8 |

SDDSC120W1 | 819.5 | 819.8 | 0.2 | 15.2 | 16.1 | 45.5 |

SDDSC120W1 | 819.8 | 820.5 | 0.7 | 0.2 | 0.0 | 0.3 |

SDDSC120W1 | 820.5 | 821.4 | 1.0 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 822.2 | 823.1 | 1.0 | 0.3 | 0.0 | 0.4 |

SDDSC120W1 | 823.1 | 823.8 | 0.6 | 0.3 | 0.0 | 0.3 |

SDDSC120W1 | 826.3 | 826.6 | 0.3 | 14.4 | 0.0 | 14.4 |

SDDSC120W1 | 831.1 | 831.6 | 0.5 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 831.6 | 831.9 | 0.3 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 832.4 | 833.0 | 0.6 | 0.5 | 0.0 | 0.5 |

SDDSC120W1 | 833.0 | 833.4 | 0.4 | 0.5 | 0.0 | 0.5 |

SDDSC120W1 | 833.4 | 833.8 | 0.4 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 833.8 | 834.0 | 0.2 | 3.0 | 0.0 | 3.1 |

SDDSC120W1 | 834.0 | 834.4 | 0.4 | 1.3 | 0.2 | 1.7 |

SDDSC120W1 | 834.4 | 835.2 | 0.8 | 0.4 | 0.0 | 0.4 |

SDDSC120W1 | 835.2 | 835.5 | 0.3 | 0.3 | 0.0 | 0.3 |

SDDSC120W1 | 835.5 | 836.3 | 0.9 | 0.3 | 0.0 | 0.3 |

SDDSC120W1 | 836.3 | 836.8 | 0.4 | 0.7 | 0.0 | 0.8 |

SDDSC120W1 | 836.8 | 837.1 | 0.4 | 2.2 | 0.0 | 2.2 |

SDDSC120W1 | 841.2 | 842.3 | 1.1 | 5.0 | 0.0 | 5.0 |

SDDSC120W1 | 843.7 | 844.3 | 0.7 | 0.1 | 0.0 | 0.2 |

SDDSC120W1 | 844.3 | 844.6 | 0.3 | 0.5 | 0.1 | 0.6 |

SDDSC120W1 | 844.6 | 844.7 | 0.2 | 0.6 | 0.3 | 1.2 |

SDDSC120W1 | 844.7 | 845.0 | 0.2 | 6.1 | 0.0 | 6.2 |

SDDSC120W1 | 848.0 | 848.5 | 0.4 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 848.5 | 848.7 | 0.2 | 34.0 | 0.0 | 34.0 |

SDDSC120W1 | 850.0 | 850.4 | 0.4 | 0.3 | 0.0 | 0.3 |

SDDSC120W1 | 853.8 | 854.3 | 0.5 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 854.3 | 855.3 | 1.0 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 855.3 | 856.0 | 0.8 | 0.4 | 0.0 | 0.4 |

SDDSC120W1 | 856.0 | 857.0 | 1.0 | 0.3 | 0.0 | 0.3 |

SDDSC120W1 | 857.0 | 858.0 | 1.0 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 858.0 | 859.0 | 1.0 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 861.0 | 861.8 | 0.8 | 0.1 | 0.0 | 0.2 |

SDDSC120W1 | 861.8 | 862.1 | 0.3 | 2.1 | 0.0 | 2.1 |

SDDSC120W1 | 863.0 | 864.0 | 1.0 | 0.2 | 0.0 | 0.3 |

SDDSC120W1 | 864.9 | 865.3 | 0.5 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 866.1 | 867.0 | 0.9 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 867.0 | 867.7 | 0.7 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 867.7 | 867.9 | 0.3 | 0.3 | 0.0 | 0.3 |

SDDSC120W1 | 868.6 | 869.4 | 0.8 | 0.4 | 0.0 | 0.4 |

SDDSC120W1 | 869.4 | 869.5 | 0.2 | 0.5 | 0.0 | 0.5 |

SDDSC120W1 | 869.5 | 869.8 | 0.3 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 869.8 | 870.8 | 1.1 | 0.1 | 0.0 | 0.2 |

SDDSC120W1 | 870.8 | 871.0 | 0.2 | 0.3 | 0.0 | 0.4 |

SDDSC120W1 | 871.0 | 871.4 | 0.3 | 0.1 | 0.2 | 0.4 |

SDDSC120W1 | 876.7 | 877.0 | 0.3 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 878.1 | 878.4 | 0.3 | 0.1 | 0.1 | 0.2 |

SDDSC120W1 | 886.1 | 886.5 | 0.4 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 886.5 | 886.7 | 0.2 | 0.8 | 0.0 | 0.8 |

SDDSC120W1 | 888.3 | 889.3 | 1.0 | 0.1 | 0.1 | 0.2 |

SDDSC120W1 | 891.0 | 891.9 | 0.9 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 891.9 | 892.8 | 0.9 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 892.8 | 893.3 | 0.4 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 893.3 | 893.7 | 0.4 | 4.0 | 0.0 | 4.0 |

SDDSC120W1 | 893.7 | 894.3 | 0.6 | 0.1 | 0.0 | 0.2 |

SDDSC120W1 | 894.3 | 894.4 | 0.2 | 5.4 | 0.0 | 5.4 |

SDDSC120W1 | 894.4 | 895.3 | 0.8 | 0.1 | 0.0 | 0.2 |

SDDSC120W1 | 896.1 | 896.9 | 0.8 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 899.6 | 900.0 | 0.5 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 901.0 | 901.4 | 0.4 | 0.6 | 0.0 | 0.6 |

SDDSC120W1 | 902.3 | 902.5 | 0.2 | 1.0 | 0.0 | 1.0 |

SDDSC120W1 | 903.8 | 904.3 | 0.4 | 0.4 | 0.0 | 0.4 |

SDDSC120W1 | 904.3 | 904.5 | 0.2 | 0.3 | 0.0 | 0.4 |

SDDSC120W1 | 904.5 | 904.8 | 0.3 | 0.7 | 0.0 | 0.7 |

SDDSC120W1 | 904.8 | 905.4 | 0.5 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 905.4 | 905.5 | 0.1 | 0.3 | 0.0 | 0.3 |

SDDSC120W1 | 905.5 | 905.9 | 0.4 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 905.9 | 906.4 | 0.5 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 909.3 | 910.2 | 0.8 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 910.2 | 910.3 | 0.1 | 0.5 | 0.0 | 0.5 |

SDDSC120W1 | 913.9 | 914.3 | 0.4 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 914.3 | 914.6 | 0.3 | 0.6 | 0.0 | 0.6 |

SDDSC120W1 | 915.4 | 916.3 | 0.9 | 0.3 | 0.0 | 0.3 |

SDDSC120W1 | 916.3 | 917.3 | 1.0 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 920.1 | 920.4 | 0.3 | 0.4 | 0.0 | 0.4 |

SDDSC120W1 | 920.9 | 921.1 | 0.3 | 0.6 | 0.0 | 0.6 |

SDDSC120W1 | 921.1 | 922.2 | 1.1 | 0.4 | 0.0 | 0.4 |

SDDSC120W1 | 922.7 | 923.6 | 0.9 | 0.4 | 0.0 | 0.5 |

SDDSC120W1 | 935.3 | 935.6 | 0.2 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 936.5 | 936.8 | 0.2 | 0.3 | 0.0 | 0.3 |

SDDSC120W1 | 936.8 | 937.3 | 0.5 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 937.3 | 937.5 | 0.2 | 0.1 | 0.0 | 0.2 |

SDDSC120W1 | 939.9 | 940.4 | 0.5 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 940.4 | 940.7 | 0.3 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 941.5 | 942.3 | 0.8 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 942.3 | 942.7 | 0.5 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 942.7 | 943.1 | 0.4 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 943.1 | 943.5 | 0.4 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 944.1 | 944.7 | 0.6 | 0.5 | 0.0 | 0.5 |

SDDSC120W1 | 945.8 | 946.0 | 0.2 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 959.3 | 959.8 | 0.4 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 959.8 | 960.1 | 0.3 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 960.1 | 960.7 | 0.6 | 0.5 | 0.0 | 0.5 |

SDDSC120W1 | 964.1 | 964.3 | 0.2 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 965.3 | 965.5 | 0.2 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 969.1 | 969.2 | 0.1 | 0.8 | 0.0 | 0.8 |

SDDSC120W1 | 969.2 | 969.6 | 0.4 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 969.6 | 969.9 | 0.4 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 972.5 | 973.4 | 0.9 | 0.5 | 0.0 | 0.5 |

SDDSC120W1 | 981.5 | 981.7 | 0.3 | 0.3 | 0.0 | 0.3 |

SDDSC120W1 | 981.7 | 982.2 | 0.4 | 0.7 | 0.0 | 0.7 |

SDDSC120W1 | 982.2 | 982.5 | 0.4 | 1.8 | 0.0 | 1.8 |

SDDSC120W1 | 989.5 | 989.9 | 0.4 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 989.9 | 990.7 | 0.8 | 0.5 | 0.0 | 0.5 |

SDDSC120W1 | 993.0 | 993.3 | 0.3 | 0.2 | 0.0 | 0.3 |

SDDSC120W1 | 993.3 | 993.6 | 0.4 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 993.6 | 993.8 | 0.1 | 0.3 | 0.0 | 0.3 |

SDDSC120W1 | 994.4 | 995.1 | 0.7 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 995.1 | 995.3 | 0.2 | 0.4 | 0.0 | 0.4 |

SDDSC120W1 | 995.3 | 996.0 | 0.7 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 1002.9 | 1003.4 | 0.5 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 1003.4 | 1004.5 | 1.1 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 1004.5 | 1005.1 | 0.6 | 0.4 | 0.0 | 0.4 |

SDDSC120W1 | 1005.1 | 1005.3 | 0.2 | 0.8 | 0.0 | 0.8 |

SDDSC120W1 | 1005.3 | 1005.5 | 0.2 | 0.3 | 0.0 | 0.3 |

SDDSC120W1 | 1005.5 | 1006.4 | 0.9 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 1006.4 | 1007.3 | 0.9 | 0.3 | 0.0 | 0.3 |

SDDSC120W1 | 1008.7 | 1008.9 | 0.2 | 0.5 | 0.0 | 0.5 |

SDDSC120W1 | 1008.9 | 1009.6 | 0.7 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 1009.6 | 1010.1 | 0.5 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 1010.1 | 1011.2 | 1.1 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 1011.2 | 1012.3 | 1.1 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 1015.2 | 1015.6 | 0.4 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 1015.6 | 1015.8 | 0.2 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 1016.8 | 1017.1 | 0.2 | 0.3 | 0.0 | 0.3 |

SDDSC120W1 | 1017.1 | 1017.6 | 0.5 | 0.3 | 0.0 | 0.3 |

SDDSC120W1 | 1017.6 | 1018.2 | 0.7 | 0.3 | 0.0 | 0.3 |

SDDSC120W1 | 1018.2 | 1019.0 | 0.8 | 0.1 | 0.0 | 0.2 |

SDDSC120W1 | 1021.1 | 1022.0 | 0.9 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 1024.2 | 1024.5 | 0.3 | 0.3 | 0.0 | 0.3 |

SDDSC120W1 | 1030.0 | 1030.4 | 0.4 | 0.4 | 0.0 | 0.4 |

SDDSC120W1 | 1030.4 | 1030.8 | 0.4 | 0.1 | 0.0 | 0.1 |

SDDSC120W1 | 1030.8 | 1031.7 | 0.9 | 1.1 | 0.0 | 1.1 |

SDDSC120W1 | 1031.7 | 1031.9 | 0.2 | 0.7 | 0.0 | 0.8 |

SDDSC120W1 | 1031.9 | 1033.0 | 1.1 | 0.2 | 0.0 | 0.2 |

SDDSC120W1 | 1033.0 | 1034.0 | 1.0 | 0.1 | 0.0 | 0.2 |

SDDSC120W1 | 1035.3 | 1035.5 | 0.2 | 0.2 | 0.0 | 0.2 |

JORC Table 1

Section 1 Sampling Techniques and Data

Criteria | JORC Code explanation | Commentary |

|---|---|---|

Sampling techniques |

|

|

Drilling techniques |

|

|

Drill sample recovery |

|

|

Logging |

|

|

Sub-sampling techniques and sample preparation |

|

|

Quality of assay data and laboratory tests |

|

|

Verification of sampling and assaying |

|

|

Location of data points |

|

|

Data spacing and distribution |

|

|

Orientation of data in relation to geological structure |

|

|

Sample security |

|

|

Audits or reviews |

|

|

Section 2 Reporting of Exploration Results

Criteria | JORC Code explanation | Commentary | ||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mineral tenement and land tenure status |

|

| ||||||||||||||||||||||||||||||

Exploration done by other parties |

|

Rock chip sampling around Christina, Apollo and Golden Dyke mines.

Exploration focused on finding low grade, high tonnage deposits. The tenements were relinquished after the area was found to be prospective but not economic.

Exploration targeting open cut gold mineralization peripheral to SXG tenements.

Targeting shallow, low grade gold. Trenching around the Golden Dyke prospect and results interpreted along with CRAs costeans. 29 RC/Aircore holes totalling 959 m sunk into the Apollo, Rising Sun and Golden Dyke target areas. ELs 4460 & 4987 - Beadell Resources Ltd

ELs 4460 and 4497 were granted to Beadell Resources in November 2007. Beadell successfully drilled 30 RC holes, including second diamond tail holes in the Golden Dyke/Apollo target areas.

Mawson drilled 30 holes for 6,928 m and made the first discoveries to depth. | ||||||||||||||||||||||||||||||

Geology |

|

| ||||||||||||||||||||||||||||||

Drill hole Information |

|

| ||||||||||||||||||||||||||||||

Data aggregation methods |

|

| ||||||||||||||||||||||||||||||

Relationship between mineralization widths and intercept lengths |

|

| ||||||||||||||||||||||||||||||

Diagrams |

|

| ||||||||||||||||||||||||||||||

Balanced reporting |

|

| ||||||||||||||||||||||||||||||

Other substantive exploration data |

|

The metallurgical characterization test work included:

| ||||||||||||||||||||||||||||||

Further work |

|

|

SOURCE: Southern Cross Gold Consolidated Ltd.