Adoption of PrintStator CAD and premium performance printed circuit board stator machines can reduce data center energy consumption and costs.

NEEDHAM, MASSACHUSETTS / ACCESS Newswire / February 19, 2025 / ECM's Dan Lisowksy will speak at the Motor, Drive Systems and Magnetics Conference in Tallahassee, Florida, February 19 at 2:30pm. Lisowsky, who is head of ECM PCB Stator Tech's Industrial OEM Products Division, will present on the benefits of PCB Stator electric motor design for data center cooling. MDSM 2025 participants are welcome to attend Dan's presentation and engage in a question-and-answer session.

ECM is an electric motor design software technology services firm. The Boston-based company recently released a new report on the advantages of PCB Stator electric motor design for global data centers, "Optimizing Data Center Efficiency with ECM PCB Stator Motors,"

Dan Lisowsky will speak to insights from that report in his MDSM 2025 session.

Challenges in Data Center Efficiency

In the case study, ECM highlights the surge in global energy consumption from increased data center demand. "Data centers consumed 130 TWh of electricity in 2022, accounting for 2.5% of total U.S. energy usage. This figure is projected to triple by 2030."

ECM's report then underscores the centrality of HVAC and electric motors to these facilities.

"Cooling systems account for 37% of the energy they use. As data centers strive to improve efficiency, lower costs, and align with sustainability goals, the motor systems within their cooling mechanisms play a crucial role."

According to ECM, additional challenges in achieving data center efficiency include the following:

Material and Resource Constraints

Design and Operational Inefficiencies

Speed, Vibration, and EMI Management; and

Shipping and Maintenance Costs

Advantages of PCB Stator Motor Design

ECM's case study then outlines the solutions its model brings to overcoming data center efficiency and cost challenges.

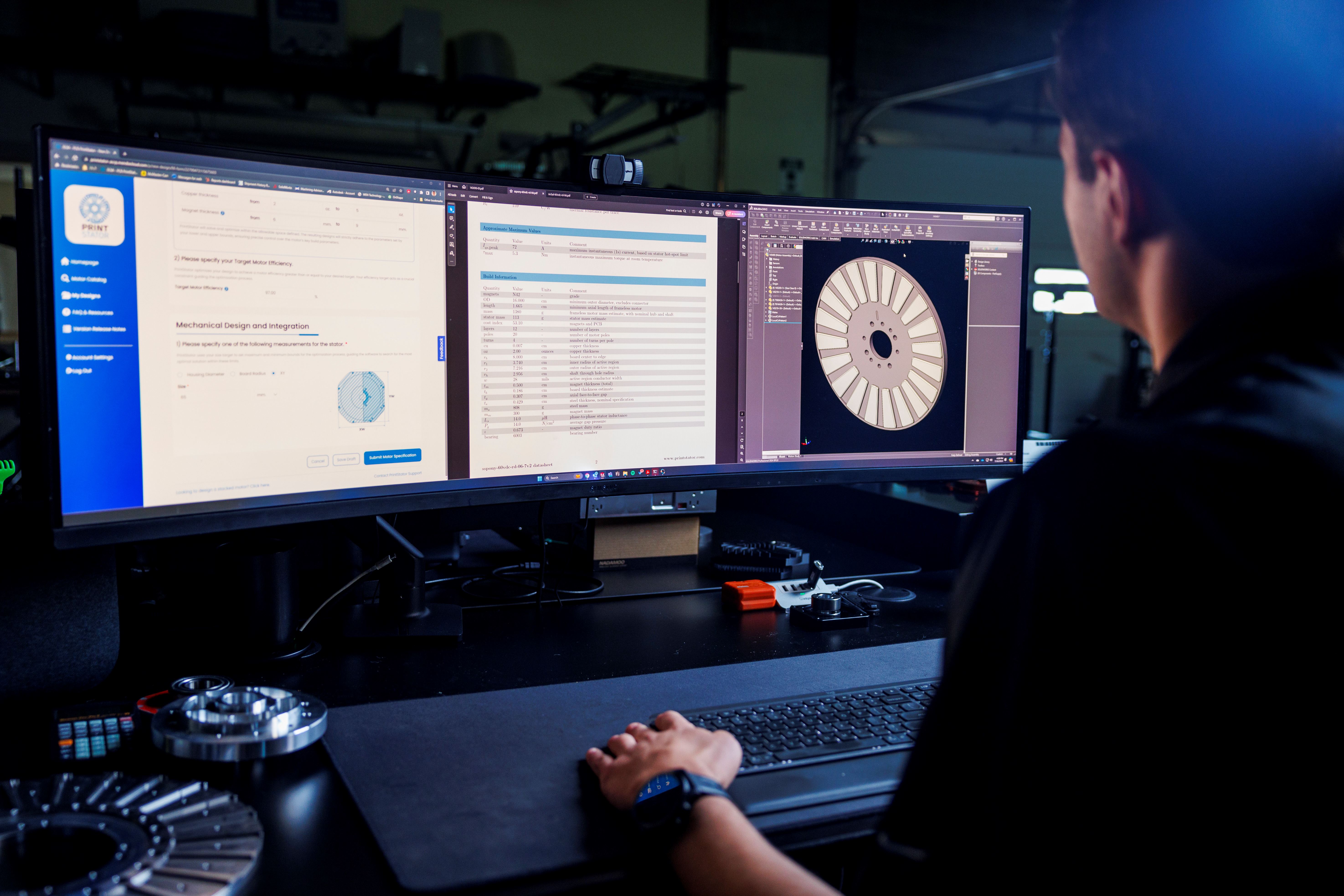

ECM's PrintStator Motor CAD electric motor design platform.

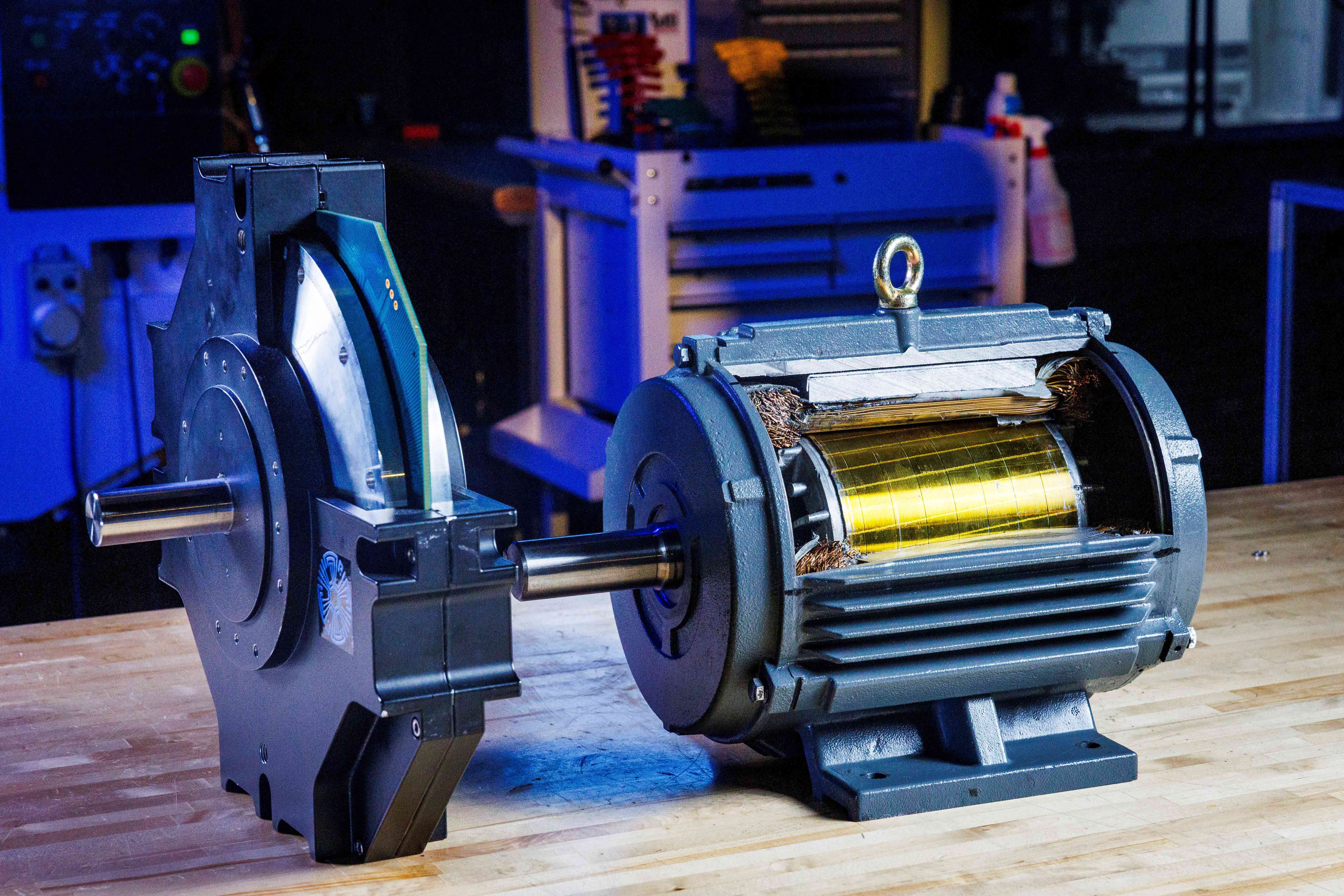

As a company, ECM pairs printed-circuit-board (PCB Stator) technology to advanced Motor CAD. The combination enables innovators to optimize electric motors that are lighter, smaller, quieter, and more energy efficient.

Those wishing to leverage ECM's innovation can do so via three core product offerings:

PrintStator SaaS

Pre-designed PCB Stator Motor Evaluation Kits; and

ECM's advanced prototyping services

As detailed in, "Optimizing Data Center Efficiency with ECM PCB Stator Motors," ECM's technology offering provides the following solutions:

Premium Efficiency -- PrintStator designed, PCB Stator motors achieve efficiencies up to 94%.

Full Customization -- ECM's PrintStator Motor CAD enables data center operators to design motors to precise performance and dimensional specs.

Lightweight and Compact Design -- By replacing the bulky copper-wound stator in conventional electric motors with an ultra-thin disk, PCB Stator motors reduce weight by up to 70%.

Continuous Operation -- ECM motors are designed for robust, continuous operation, ensuring high reliability and minimizing downtime risks in mission-critical environments, such as data centers.

Efficient Heat Dissipation -- ECM's patented thermal management solutions effectively dissipate heat without additional cooling systems, improving reliability and energy efficiency.

Sustainability -- ECM's PrintStator designed motors use up to 80% less copper than conventional options and are more durable (with lower maintenance and longer life cycles).

At MDSM 2025, Dan Lisowsky will speak in detail on these solutions for data centers and welcome questions.

About ECM

ECM PCB Stator Tech is an electric motor design software and technology company headquartered in the U.S. ECM pairs advanced Motor CAD and patented PCB Stator-printed circuit board-technology to create next generation machines for multiple applications.

ECM's award-winning PrintStator software powers the design, manufacture, and integration of PCB Stator motors that are lighter, quieter, and more compact and energy efficient. ECM designed motors achieve efficiencies in excess of 90%, while requiring just 20% of the raw materials to produce.

ECM has collaborated with multiple organizations to create optimized motor solutions across a variety of verticals. Those span HVAC, E-Mobility, Medical, Robotics, Aerospace, Haptics, Simulated Inertia, Renewable Energy, Aerospace, and Consumer Electronics.

ECM's design partners include consumer electronics leader Thrustmaster, publicly traded aerospace and technology company L3 Harris, global electronics manufacturer Celestica, marine and rail component leader B. Hepworth, global engineering and manufacturing services firm East West Manufacturing, and consumer electronics startup Nodo Film Systems.

ECM is a 2024 and 2025 CES Innovation Awards Honoree and winner of four International SaaS Awards-including SaaS Solution of The Year, Best SaaS Product for CSR, Sustainability and ESG, and Best SaaS Product for Engineering Management, PLM Or CAD. ECM's PrintStator software is also a winner of the Automate Innovation Awards, Machine Design IDEA Awards, and Design World LEAP Awards.

ECM maintains offices in Boston (MA), Bozeman (MT), and a business development representative in Europe.

You can learn more about ECM's PCB Stator solutions and PrintStator Motor CAD platform at www.pcbstator.com and in these videos: "How Does a PCB Stator Work?" and "Designing Sustainable Electric Motors."

Contact Information

Jake Bright

Direct of Communications

jbright@pcbstator.com

SOURCE: ECM PCB Stator Tech

View the original press release on ACCESS Newswire