New system improves quality and efficiency

Originally published on 3M News Center

NORTHAMPTON, MA / ACCESS Newswire / February 19, 2025 / 3M has teamed up with General Motors on something that has never been done before in automotive manufacturing: automating paint repair on a moving production line.

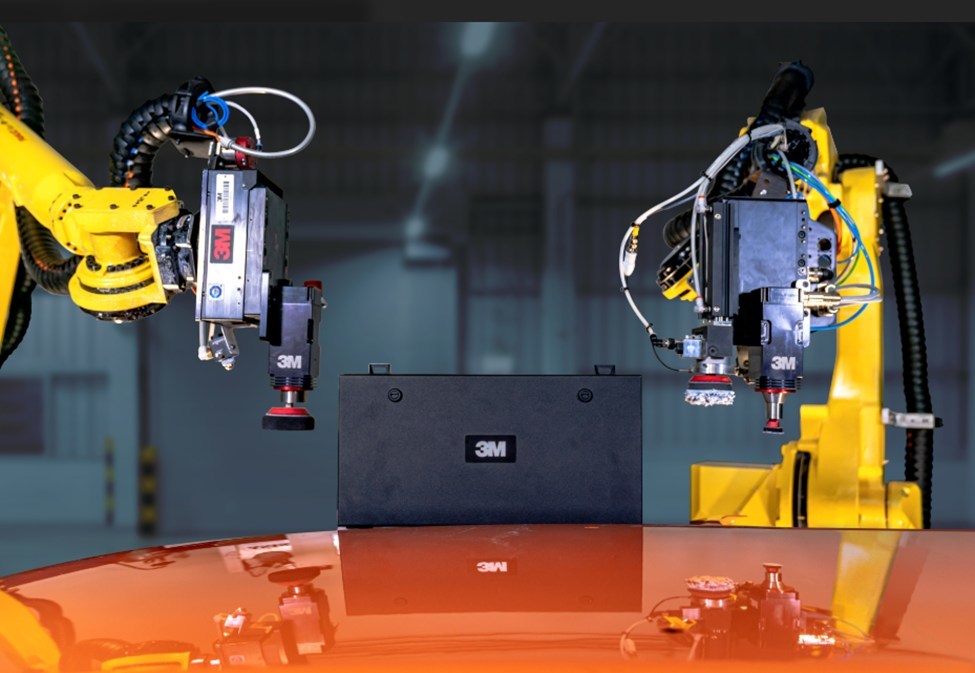

GM is using 3M's Finesse-it Robotic Paint Repair System which incorporates 3M robotics, stream motion software, process modeling, and abrasive technology to fix imperfections in the paint topcoat on vehicles coming off the assembly line. GM installed the system at its Spring Hill, Tennessee, plant where the automaker manufactures Cadillac SUVs, and is exploring more installations and applications of the system at other facilities in the future.

3M helped GM develop a solution to a challenge that all automakers face - finding and fixing paint imperfections as vehicles roll through the assembly line. When repairs are done by hand, they can be labor-intensive and unpredictable. 3M's Finesse-it Robotic Paint Repair System makes that process more efficient and accurate.

Here's how it works: First, a high-tech vision system checks the car from all angles to find and categorize any imperfections in the paint topcoat. This data helps the system create the best paint repair plan. Next, the car moves to sanding and polishing. Robots follow precise instructions to fix the imperfections using 3M's software, hardware, special abrasives and polishes. The system can even work on a moving assembly line, which is how GM is using it at Spring Hill.

Ryan Odegaard, GM's Director of Paint Polymers and Additive Manufacturing at GM, called implementing the 3M Finesse-it Paint Repair System the "final frontier of automation" for the automaker's high-volume paint shop. Odegaard spoke about how GM and 3M are partnering on robotic paint repair at 3M's Thought Leadership Theater at CES in Las Vegas in January.

"At GM, many of our processes are already automated and this is a very complicated area to think about automating," Odegaard said. "If you have a customer-facing product, you have to make sure that that paint finish is perfect because it's the first thing you see when you go into a dealership."

Odegaard added that whether it's an automotive or industrial paint process, there's always a chance of surface imperfections. Those need to be fixed at the end of the process and up until now that's been one of the most labor-intensive steps for car manufacturers.

"Basically, you have layers of inspection and layers of people who are interfacing with that surface to correct those surface issues," Odegaard said.

GM looked to 3M, with its expertise in material science and abrasive technology, to help the automaker automate that process. To create a solution, 3M leveraged its decades of expertise in robotics, abrasives and software.

At CES, Marcus Pelletier, Global R&D Director of Systems Development at 3M, said that all comes together as the robotic arms, tipped with 3M abrasive discs, descend on the vehicle to fix surface imperfections in the paint job.

"We are streaming information to that robot approximately every 10 milliseconds," Pelletier said. "Because we're doing it in real-time, if we detect something when the tool touches the car … we can modify our trajectories dynamically on the fly so that we end in the right spot every time."

3M's work with GM to revolutionize and simplify the automaker's paint repair system, shows that 3M is committed to taking on customers' challenging problems with continuous innovation in abrasives and robotics.

"We don't want to tackle the easy problems, the easy problems others are solving," said Pelletier. "We wanted to find the hard problems and showcase our capabilities and deliver that value, and we're going to continue doing that."

View additional multimedia and more ESG storytelling from 3M on 3blmedia.com.

Contact Info:

Spokesperson: 3M

Website: https://www.3blmedia.com/profiles/3m

Email: info@3blmedia.com

SOURCE: 3M