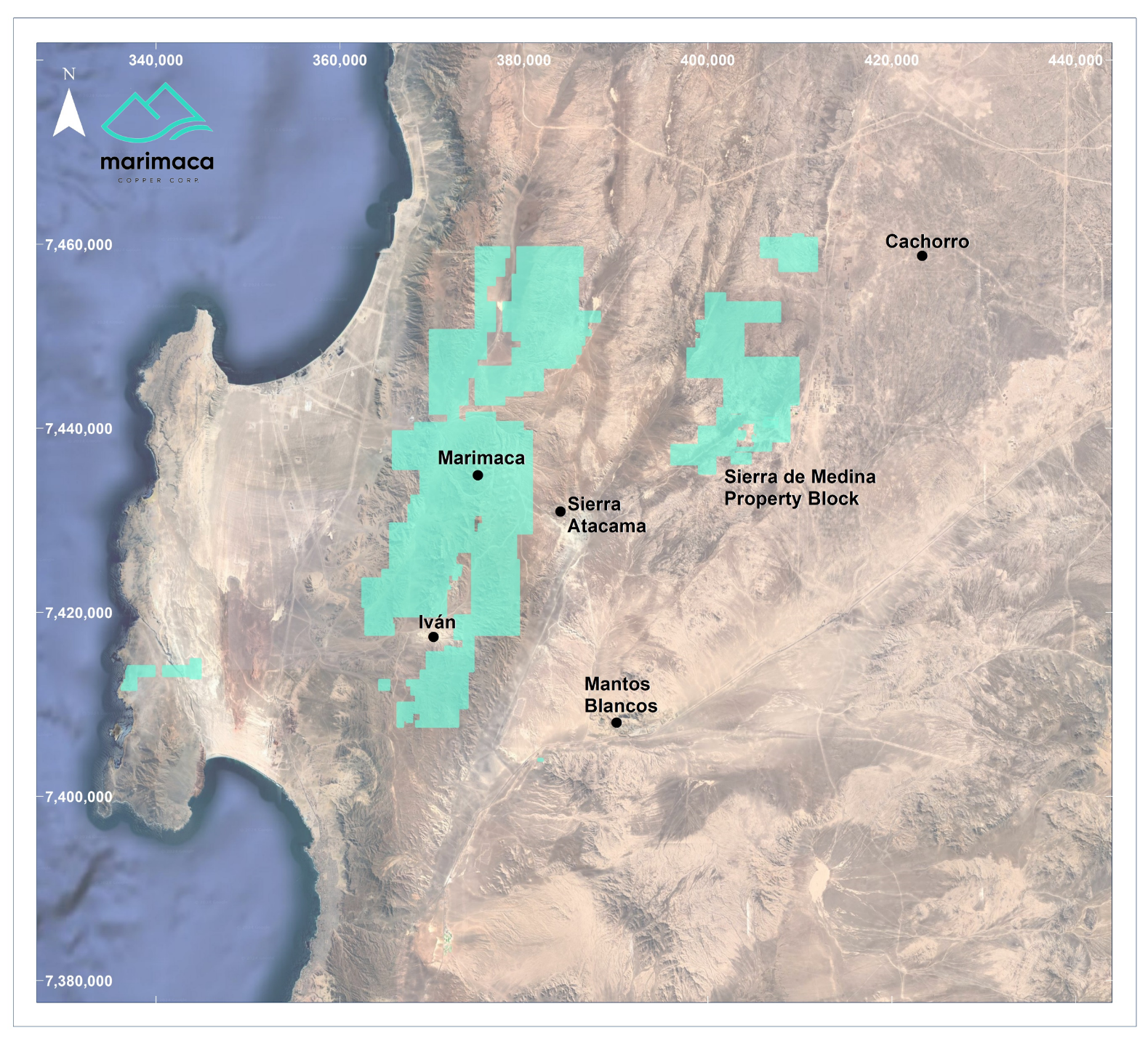

VANCOUVER, British Columbia, April 15, 2025 (GLOBE NEWSWIRE) -- Marimaca Copper Corp. ("Marimaca Copper" or the "Company" (TSX: MARI) is pleased to announce results from the re-interpretation of data in the Pampa Medina Project Area ("Pampa Medina") which incorporates the Pampa Medina and Madrugador deposits and the newly identified Pampa West oxide zone, and is located approximately 25km from the Company's flagship Marimaca Oxide Deposit ("MOD").

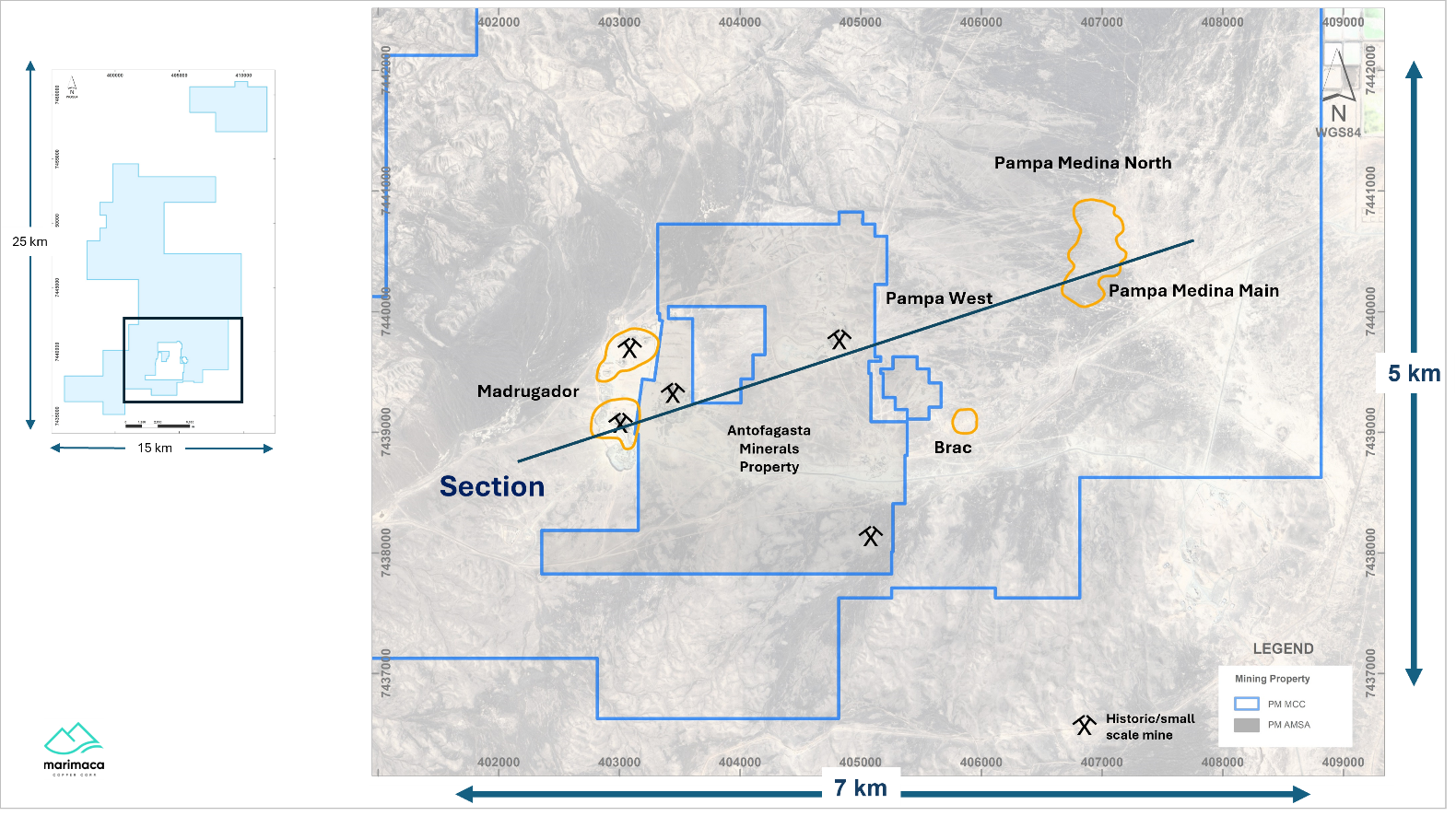

The Company also announces results from five broad reconnaissance exploration holes, which were designed to identify the limits of the mineralized horizon. This drilling, when combined with the full review and relogging of historical drilling, shows consistent broad zones of oxide copper mineralization of variable grades in the same stratigraphic horizon over an area of approximately 5km by 4km, which is the current defined extent of the manto horizon. Potential exists for further extensions in all directions, with ongoing step out programs.

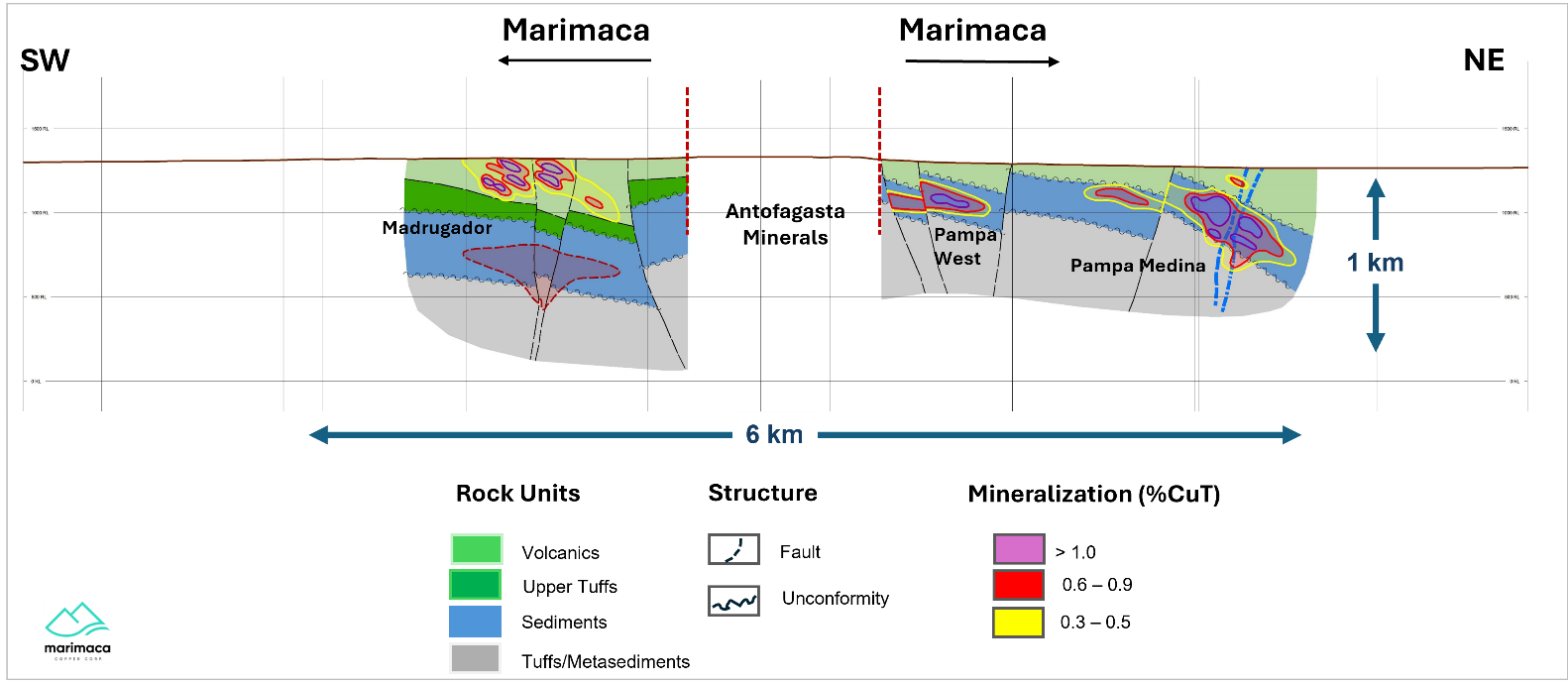

Based on the extensive work completed, including the new drilling results extending Pampa Medina, the Company believes that Pampa Medina may be the central part of a larger manto system, which genetically links the Madrugador, Pampa Medina, Sierra Valenzuela (Antofagasta Minerals) and Pampa Norte deposits. It was this interpretation which led to the discovery of the new, shallow, oxide opportunity at Pampa West. Based on these results, the Company will continue with its strategy of large-scale step-out holes from known mineralization, and deep sulphide-target drilling to try to identify the limits of the system.

Marimaca is considering alternatives for a significantly expanded program for the balance of 2025 to include both reverse circulation ("RC") and diamond drilling. The objectives of this program will be to continue to step out to identify the limits of the system, to test the deeper units for primary copper mineralization and to delineate areas for potential extensions of near-surface oxide mineralization.

Sergio Rivera, VP Exploration, commented:

"Our extensive reviews of existing data, our geophysical campaigns and the results from our initial step out discovery campaign indicate Pampa Medina is likely to be part of a much larger manto system, which extends at least 5km east to west and more than 4km north and south. As with all large-scale mineralizing systems, there is zonation and variability of grade, but we are excited about both the continuity of mineralization in the productive sedimentary and tuff horizons and the large-scale mineralizing events which have impacted them across this area.

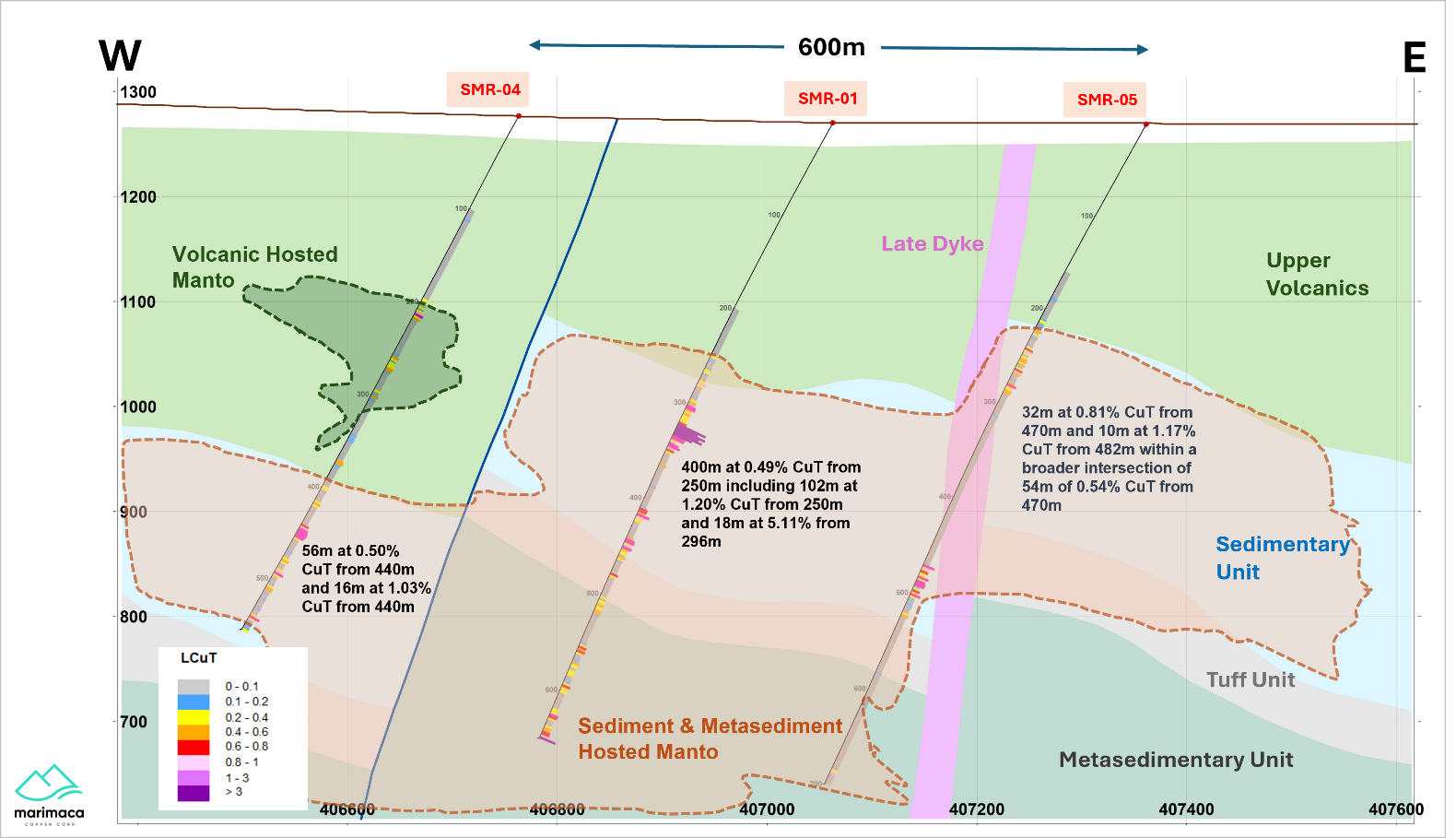

"The significant east-west step outs at Pampa Norte, either side of the fantastic drill hole at SMR-01, encountered offset faulting and a series of barren dykes, which are important controls of mineralization. However, we can now clearly see the potential for 1,000m of east-west extent of the mineralized envelope for Pampa Medina, which becomes important for resource growth potential in future programs.

"Our exploration model, which hypothesised that the majority of the historical drilling was not deep enough to targeting the productive sedimentary units, has been confirmed and we see numerous opportunities for further discovery and extension from our existing deposits."

Hayden Locke, President and CEO, commented:

"With the Pampa Norte Extension we see a strong potential for additional leachable mineralisation in the short term, and we will move to a de-lineation program later this year. In the longer term, the potential for a large scale discovery is very much intact and we intend to test our exploration model thoroughly.

"This is the first time that the Pampa Medina system has been largely consolidated under one operator, and as such the first time that all available geological information has been consolidated and reviewed as one. While previous interpretations considered each of our identified zones as separate and distinct deposits, we are excited about the potential for Pampa Medina to rather represent a single, large scale mineralised system."

Highlights

- Pampa Medina now defined by five core zones interpreted to be genetically linked (see Figure 2):

- Pampa Medina Main, Pampa Norte, Pampa Medina West, Sierra Valenzuela (Antofagasta Minerals) and Madrugador

- Pampa Medina Main, Pampa Norte, Pampa Medina West, Sierra Valenzuela (Antofagasta Minerals) and Madrugador

- Relogging and reinterpretation of the consolidated historical data from Pampa Medina (41,000m of drilling) and Madrugador (36,373m of drilling) indicates continuity of the manto system across the five zones

- Manto-type mineralization now identified in key stratigraphic sequences across area of interest spanning 4km x 5km (see Figure 3)

- Prior to consolidation, each zone was assumed to be an independent deposit and genetically unrelated

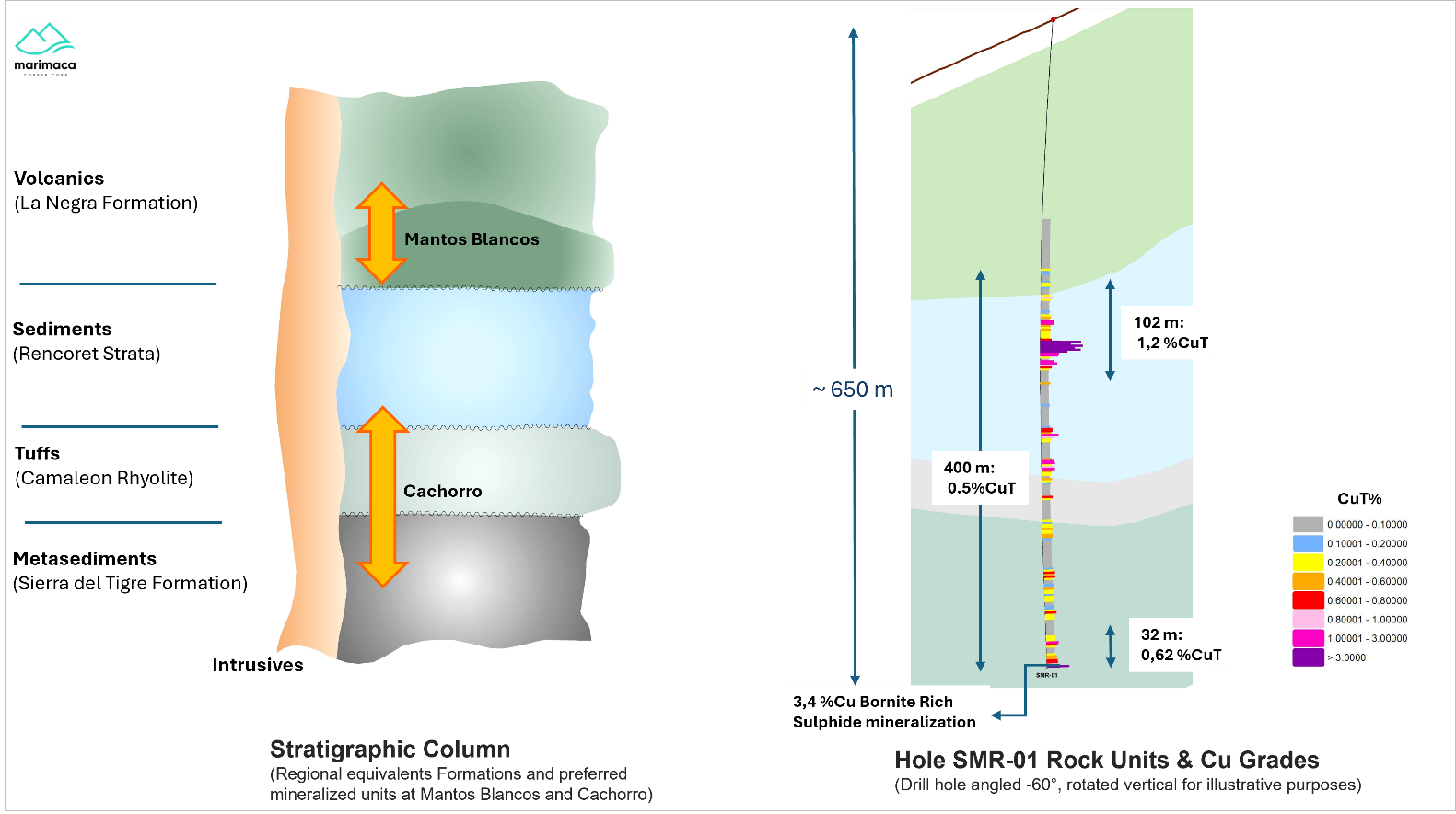

- Key stratigraphy identified across each zone (see Figure 4) with mineralization dominated by oxide copper in the middle sedimentary unit, and transitioning to chalcopyrite-bornite mineralization in the lower basement tuff and metasedimentary units

- Upper volcanic units also mineralized in the case of Madrugador (see Figure 3)

- Intensity of mineralization across the various stratigraphy illustrated well in previously reported SMR-01 (400m at 0.49% CuT from 250m including 102m at 1.20% CuT from 250m and 18m at 5.11% from 296m)

- Six reconnaissance drill holes now complete (including SMR-01)

- SMR-05 (400m step out to the east from SMR-01)

- 32m at 0.81% CuT from 470m and 10m at 1.17% CuT from 482m within a broader intersection of 54m of 0.54% CuT from 470m

- 50m at 0.42% CuT from 240m

- SMR-02 (Pampa Medina West)

- 90m at 0.40% CuT from 206m including 6m at 1.72% CuT from 290m

- 10m at 0.73% CuT from 94m

- SMR-03 (Pampa Medina West area)

- 6m at 1.03% CuT from 226m

- Intersected a series of WNW trending barren dykes which are now understood to be important mineralization controls

- SMR-04 (400m step out to the west from SMR-01) which intercept fault uplifted mineralized sediments as compared with hole SMR-01, but significant post-mineral barren dykes which truncated mineralized zones

- In the down-dropped sedimentary block (see Figure 6):

- 116m at 0.32% CuT including 56m at 0.50% CuT from 440m and 16m at 1.03% CuT from 440m

- In the upper volcanic unit:

- 8m at 0.70% CuT from 210m

- 18m at 0.31% CuT from 258m

- In the down-dropped sedimentary block (see Figure 6):

- SMR-06 (400m north stepout from SMR-01) intercepted low grade mineralized volcanics down-dropped by an interpreted WNW fault and dyke corridor which interrupted the favourable sediment unit extension toward the north

- 8m at 0.58% CuT from 302m including 2m at 1.30% CuT from 304m

- 8m at 0.58% CuT from 302m including 2m at 1.30% CuT from 304m

- SMR-05 (400m step out to the east from SMR-01)

- Further drilling in 2025 will focus on further step-out drilling, as well as infill drilling in the Madrugador, Pampa Medina West and Pampa Medina Main areas to support and validate historical drilling results, a sample set reported below*:

- Pampa Medina Main Historical Drilling

- 122m at 1.61% CuT from 199m from DDHSM-06 (Rayrock, 2012-2013)

- 117m at 1.15% CuT from 142.5m from DDHSM-04 (Rayrock, 2012-2013)

- 82m at 1.49% CuT from 258m from DDHSM-26 (Rayrock, 2012-2013)

- 102m at 1.14% CuT from 277m from DDHSM-35 (Rayrock, 2012-2013)

- 135m at 1.22% CuT from 285m from DDHSM-36 (Rayrock, 2012-2013)

- 36m at 2.75% CuT from 288m including 15m at 4.87% CuT from 309m from DDHSM-42 (Rayrock, 2012-2013)

- Madrugador Historical Drilling

- 139m at 1.32% CuT from 42m from RQM-014 (Apoquindo Minerals, 2007)

- 65.5m at 1.81% CuT from 46m from DQM-003 (Apoquindo Minerals, 2007)

- 45m at 2.16% CuT from 31m from RCV-57 (Apoquindo Minerals, 2007)

- Pampa Medina West (previously known as Brac) Historical Drilling

- 36m at 1.08% CuT from 57m from RQM-57 (Apoquindo Minerals, 2007)

- 21m at 0.91% CuT from 113m from RQM-75 (Apoquindo Minerals, 2007)

- 18m at 1.42% CuT from 229m and 51m at 0.51% CuT from 80m from DDH-SM-69 (Rayrock, 2012-2013)

- 15m at 0.75% CuT from 75m from RQM-71 (Apoquindo Minerals, 2007)

12m at 0.80% CuT from 130m from RQM-87 (Apoquindo Minerals, 2007)

- Pampa Medina Main Historical Drilling

*Reporting of Historical Drilling

Historical drilling results reported above are the results from drilling activities conducted by past operators and not Marimaca. Marimaca is not treating these drill results as current however the Qualified/Competent Person has reviewed, re-logged and digitized all historical drilling completed at Pampa Medina. Marimaca considers these historical results relevant to assist with target definition for future exploration programs, however readers are cautioned that there has been insufficient exploration to define any mineral resource and it is uncertain whether further exploration will result in the target being delineated as a mineral resource.

Relevant information pertaining to the drill holes is listed in Table 1 annexed to this Announcement.

Overview of Pampa Medina

Pampa Medina is a manto-style copper deposit dominantly hosted in Lower Jurassic sedimentary units (sandstones and black shales) overlain by Jurassic andesitic volcanics and underlaying by a Paleozoic to Triassic complex of metasediments and intrusions, which are also an important host of mineralization. Copper is found predominantly in oxide species atacamite and chrysocolla and both secondary and primary chalcocite. Copper oxide mineralization has been dominant in the upper unit of sandstones and volcaniclastics and an underlying black shale unit at Pampa Medina Main. At Madrugador, mineralization is hosted in the upper unit of andesitic volcanics with the (presumably) underlying sediments remaining untested. In the basement, beneath the sediments, rhyolitic tuffs and metasediments are dominant and mineralization appears to transition to primary chalcopyrite and bornite mineralization as encountered in drill hole SMR-01. Historical drilling at Pampa Medina (across all zones) was generally limited to a depth of ~400m, potentially too shallow to intersect the chalcopyrite-bornite dominant manto mineralization found in SMR-01 in the lower tuff and metasediments & diorite unit at a depth of 550m+.

Further RC and combined RC-DDH drilling in Q1 2025 will continue to target the productive sedimentary horizons for high grade leachable copper at Pampa Medina Main, West, North and stepping out from each. A first diamond drill rig will test the SMR-01 deep extension, and a diamond drill rig is also being added to test for primary extensions beneath the sediments at Pampa Medina Main, as well as for deeper mineralization at Madrugador where the historical drilling is limited to only the upper andesitic volcanics (see Figure 3).

Figure 1: Regional Map - Marimaca and Sierra de Medina

Figure 1: Regional Map - Marimaca and Sierra de Medina

Figure 2 - Pampa Medina Deposit Zones

Figure 2 - Pampa Medina Deposit Zones

Figure 3 - Long Section - Madrugador to Pampa Medina Main

Figure 3 - Long Section - Madrugador to Pampa Medina Main

Figure 4 - Exploration Model Stratigraphic Column with SMR-01 for Reference

Figure 4 - Exploration Model Stratigraphic Column with SMR-01 for Reference

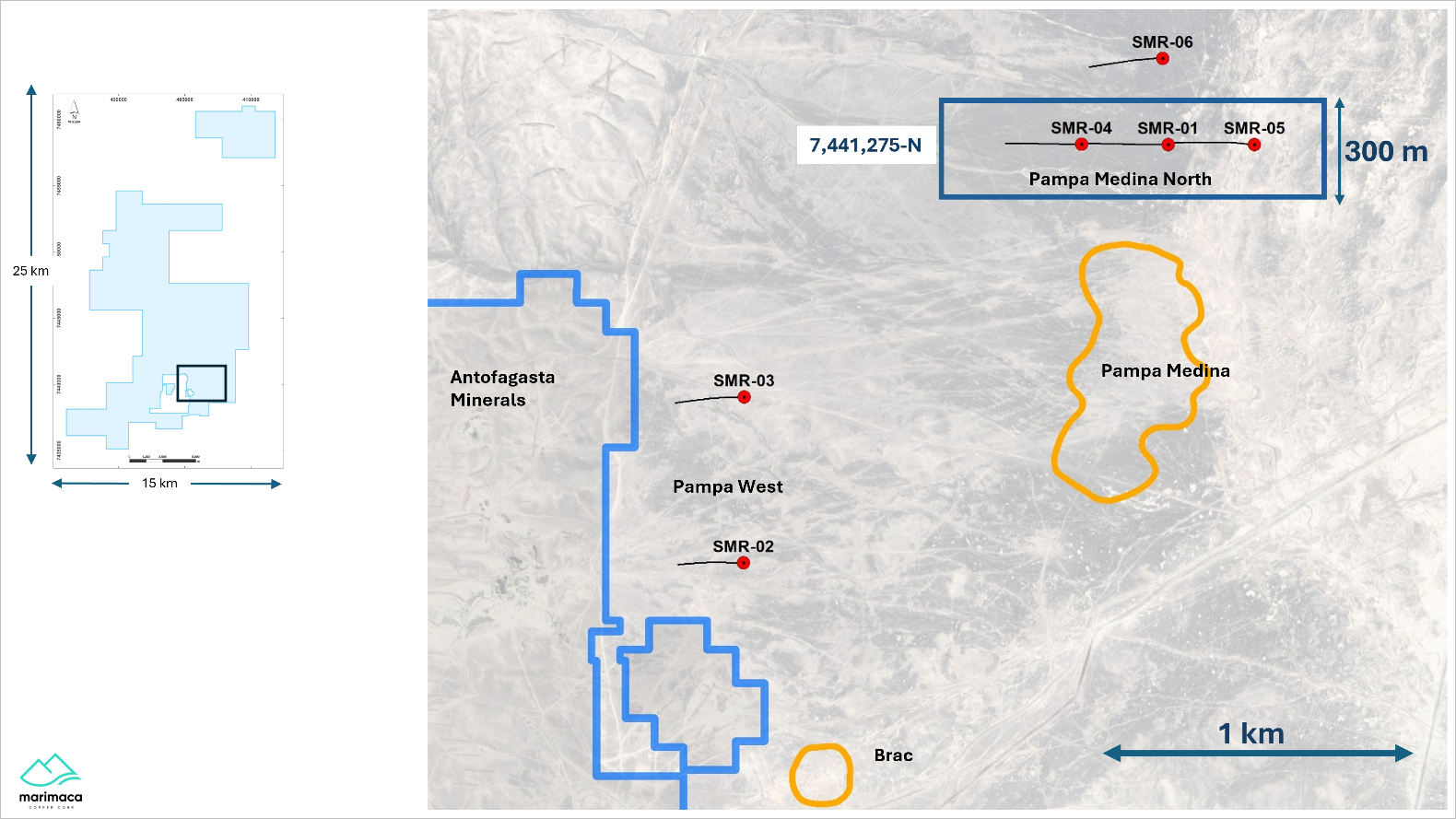

Figure 5 - Reconnaissance Drilling: Pampa Medina West and Pampa Medina Norte

Figure 5 - Reconnaissance Drilling: Pampa Medina West and Pampa Medina Norte

Figure 6 - Pampa Norte Cross Section 7,441,275N

Figure 6 - Pampa Norte Cross Section 7,441,275N

| Hole | Total Depth (m) | From (m) | To (m) | Intersection (m) | % CuT | |

SMR-01 (previously released) | 650 | 250 | 650 | 400 | 0.49 | |

| Including | 250 | 466 | 216 | 0.70 | ||

| Including | 250 | 352 | 102 | 1.20 | ||

| Including | 276 | 352 | 76 | 1.57 | ||

| Including | 296 | 352 | 56 | 2.05 | ||

| Including | 320 | 338 | 18 | 5.11 | ||

| And | 618 | 650 | 32 | 0.62 | ||

| Including | 648 | 650 | 2 | 3.43 | ||

SMR-02 | 500 | 94 | 104 | 10 | 0.73 | |

| 206 | 296 | 90 | 0.40 | |||

| Including | 290 | 296 | 6 | 1.72 | ||

| SMR-03 | 500 | 226 | 232 | 6 | 1.03 | |

SMR-04 | 556 | 210 | 218 | 8 | 0.70 | |

| 258 | 276 | 18 | 0.31 | |||

| 440 | 454 | 14 | 1.14 | |||

| 490 | 494 | 4 | 1.04 | |||

| 538 | 544 | 6 | 0.77 | |||

SMR-05 | 700 | 240 | 290 | 50 | 0.42 | |

| 470 | 524 | 54 | 0.54 | |||

| Including | 470 | 502 | 32 | 0.81 | ||

| Including | 482 | 492 | 10 | 1.17 | ||

| SMR-06 | 614 | 302 | 310 | 8 | 0.58 | |

| Including | 304 | 306 | 2 | 1.30 |

Table 1: Table of Intersections - 2025 Reconnaissance Drilling

| Hole | Easting | Northing | Elevation | Azimuth | Dip | Depth | Year | Type |

| SMR-01 | 407062.81 | 7441273.71 | 1270.17 | 270,19 | -60,67 | 650.00 | 2025 | RC |

| SMR-02 | 405593.77 | 7439826.48 | 1297.09 | 270,78 | -60,65 | 500.00 | 2025 | RC |

| SMR-03 | 405596.31 | 7440399.82 | 1300.53 | 268,84 | -59,67 | 500.00 | 2025 | RC |

| SMR-04 | 406763.42 | 7441275.72 | 1276.67 | 268,59 | -60,03 | 556.00 | 2025 | RC |

| SMR-05 | 407361.55 | 7441273.84 | 1268.80 | 270.00 | -60.00 | 700.00 | 2025 | RC |

| SMR-06 | 407043.68 | 7441573.24 | 1272.27 | 270.00 | -60.00 | 614.00 | 2025 | RC |

Table 2: Drill Collars - 2025 Reconnaissance Drilling

| Hole | Total Depth (m) | From (m) | To (m) | Intersection (m) | % CuT | |

| DDHSM-06 | 400 | 199 | 321 | 122 | 1.61 | |

| DDHSM-04 | 402 | 142.5 | 259.5 | 117 | 1.15 | |

| DDHSM-26 | 420 | 258 | 340 | 82 | 1.49 | |

| DDHSM-35 | 418.55 | 277 | 379 | 102 | 1.14 | |

| DDHSM-36 | 440.05 | 285 | 420 | 135 | 1.22 | |

| DDHSM-42 | 420 | 288 | 324 | 36 | 2.75 | |

| including | 309 | 324 | 15 | 4.87 |

Table 3: Table of intersections - Pampa Medina Main

| Hole | Easting | Northing | Elevation | Azimuth | Dip | Depth | Year | Type |

| DDHSM-04 | 406957.86 | 7440499.45 | 1270.61 | 292.50 | -72.90 | 402.00 | 2012 | DDH |

| DDHSM-06 | 407081.32 | 7440500.45 | 1267.52 | 271.39 | -46.04 | 400.00 | 2012 | DDH |

| DDHSM-26 | 407082.46 | 7440900.10 | 1268.44 | 266.73 | -57.46 | 420.00 | 2013 | DDH |

| DDHSM-35 | 407053.83 | 7440540.16 | 1269.28 | 271.15 | -55.26 | 418.55 | 2013 | DDH |

| DDHSM-36 | 407153.85 | 7440539.86 | 1267.62 | 263.67 | -46.90 | 440.05 | 2013 | DDH |

| DDHSM-42 | 407120.09 | 7440752.99 | 1268.14 | 271.33 | -70.88 | 420.00 | 2013 | DDH |

Table 4: Drill Collars - Pampa Medina Main

| Hole | Total Depth (m) | From (m) | To (m) | Intersection (m) | % CuT | |

| RQM-57 | 150 | 57 | 93 | 36 | 1.08 | |

| RQM-75 | 180 | 113 | 134 | 21 | 0.91 | |

| RQM-71 | 150 | 75 | 90 | 15 | 0.76 | |

| RQM-87 | 160 | 130 | 142 | 12 | 0.80 | |

| DDM-SM-69 | 280.75 | 80 | 131 | 51 | 0.44 | |

| 229 | 247 | 18 | 1.42 |

Table 5: Table of Intersections - Pampa West/Brac Historical Drilling

| Hole | Easting | Northing | Elevation | Azimuth | Dip | Depth | Year | Type |

| RQM-57 | 405897.47 | 7439123.65 | 1287.37 | 87.06 | -60.04 | 150.00 | 2007 | RC |

| RQM-75 | 405847.59 | 7439097.78 | 1288.74 | 87.80 | -60.16 | 180.00 | 2007 | RC |

| RQM-71 | 405874.36 | 7439048.47 | 1288.76 | 88.44 | -59.63 | 150.00 | 2007 | RC |

| RQM-87 | 405827.15 | 7439070.85 | 1289.69 | 91.49 | -59.38 | 160.00 | 2007 | RC |

| DDM-SM-69 | 405430.23 | 7439658.09 | 1300.53 | 20.97 | -88.33 | 280.75 | 2014 | DD |

| DDH-SM-70 | 405578.52 | 7439725.49 | 1296.00 | 270.29 | -79.56 | 277.00 | 2014 | DD |

Table 6: Drill Collars - Pampa West/Brac Historical Drilling

| Hole | Total Depth (m) | From (m) | To (m) | Intersection (m) | % CuT | |

| RQM-014 | 200 | 42 | 181 | 139 | 1.32 | |

| DQM-003 | 208.4 | 46 | 111.5 | 65.5 | 1.81 | |

| RCV-57 | 138 | 31 | 76 | 45 | 2.16 |

Table 7: Table of Intersections - Madrugador Historical Drilling

| Hole | Easting | Northing | Elevation | Azimuth | Dip | Depth | Year | Type |

| RQM-014 | 403057.43 | 7439114.33 | 1325.32 | 350.65 | -89.39 | 200.00 | 2007 | RC |

| DQM-003 | 403056.52 | 7439126.82 | 1323.88 | 64.91 | -89.69 | 208.40 | 2007 | DDH |

| RCV-57 | 403067.89 | 7439051.19 | 1321.80 | 270.00 | -60.00 | 138.00 | 2007 | RC |

Table 8: Drill Collars - Madrugador Historical Drilling

Sampling and Assay Protocols

True widths cannot be determined with the information available at this time. RC holes drilled by Marimaca were sampled on a 2m continuous basis, with dry samples riffle split on site and one quarter sent to the Andes Analytical Assay preparation laboratory in Copiapo and the pulps then sent to the same company laboratory in Santiago for assaying. A second quarter was stored on site for reference. Samples were prepared using the following standard protocol: drying; crushing to better than 85% passing -10#; homogenizing; splitting; pulverizing a 500-700g subsample to 95% passing -150#; and a 125g split of this sent for assaying. All samples were assayed for %CuT (total copper) and %CuS (acid soluble copper) by AAS. A full QA/QC program, involving insertion of appropriate blanks, standards and duplicates was employed with acceptable results for all current drilling. Pulps and sample rejects are stored by Marimaca Copper for future reference.

Qualified Person / Competent Person

The technical information in this news release, including the information that relates to geology, drilling and mineralization was prepared under the supervision of, or has been reviewed by Sergio Rivera, Vice President of Exploration, Marimaca Copper Corp, a geologist with more than 40 years of experience and a member of the Colegio de Geólogos de Chile and of the Institute of Mining Engineers of Chile, and who is the Qualified Person for the purposes of NI 43-101 responsible for the design and execution of the drilling program.

The information in this announcement which relates to exploration results for the Pampa Medina Project is based on, and fairly reflects, information and supporting documentation prepared by Sergio Rivera, VP Exploration of Marimaca, a Competent Person who is a member of the Comision Minera (Chilean Mining Commission), Colegio de Geólogos de Chile and of the Institute of Mining Engineers of Chile. Mr. Rivera has sufficient experience that is relevant to the style of mineralisation and types of deposit under consideration and to the activity being undertaken to qualify as a Competent Person as defined in the 2012 Edition of the Joint Ore Reserves Committee Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves. Mr. Rivera consents to the inclusion in this announcement of the matters based on his information in the form and context in which it appears.

Contact Information

For further information please visit www.marimaca.com or contact:

Tavistock

+44 (0) 207 920 3150

Emily Moss / Ruairi Millar

marimaca@tavistock.co.uk

Forward Looking Statements

This news release includes certain "forward-looking statements" under (without limitation) applicable Canadian securities legislation, including, without limitation, statements regarding the development of activities at Pampa Medina, the potential growth of Pampa Medina, and the discovery's potential to complement the MOD. There can be no assurance that such statements will prove to be accurate, and actual results and future events could differ materially from those anticipated in such statements. Forward-looking statements reflect the beliefs, opinions and projections on the date the statements are made and are based upon a number of assumptions and estimates that, while considered reasonable by Marimaca Copper, are inherently subject to significant business, economic, competitive, political and social uncertainties and contingencies. Many factors, both known and unknown, could cause actual results, performance or achievements to be materially different from the results, performance or achievements that are or may be expressed or implied by such forward-looking statements and the parties have made assumptions and estimates based on or related to many of these factors. Such factors include, without limitation: risks that the development activities at Pampa Medina will not progress as anticipated, or at all, risks related to share price and market conditions, the inherent risks involved in the mining, exploration and development of mineral properties, the uncertainties involved in interpreting drilling results and other geological data, fluctuating metal prices, the possibility of project delays or cost overruns or unanticipated excessive operating costs and expenses, uncertainties related to the necessity of financing, uncertainties relating to regulatory procedure and timing for permitting submissions and reviews, the availability of and costs of financing needed in the future as well as those factors disclosed in the annual information form of the Company dated March 27, 2025 and other filings made by the Company with the Canadian securities regulatory authorities (which may be viewed at www.sedar.com). Readers should not place undue reliance on forward-looking statements. Marimaca Copper undertakes no obligation to update publicly or otherwise revise any forward-looking statements contained herein whether as a result of new information or future events or otherwise, except as may be required by law.

None of the TSX, ASX or the Canadian Investment Regulatory Organization accepts responsibility for the adequacy or accuracy of this release.

This announcement was authorised for release to the ASX by the Board of Directors of the Company.

Appendix 1 - JORC Code 2012 Table 1 (ASX Listing Rule 5.7.1)

Section 1 Sampling Techniques and Data

| Criteria | JORC Code explanation | Commentary | |

| Sampling techniques |

| Marimaca Drilling:

Apoquindo Minerals 2007 Drilling

Rayrock 2012-2013 Drilling

| |

| Drilling techniques |

| Marimaca Drilling

Apoquindo Minerals 2007 Drilling

Rayrock 2012-2013 Drilling

| |

| Drill sample recovery |

| Marimaca Drilling

Apoquindo Minerals 2007 Drilling

Rayrock 2012-2013 Drilling

| |

| Logging |

| Marimaca Drilling

Apoquindo Minerals 2007 Drilling

Rayrock 2012-2013 Drilling

| |

| Sub-sampling techniques and sample preparation |

| Marimaca Drilling

Apoquindo Minerals 2007 Drilling

Rayrock 2012-2013 Drilling

| |

| Quality of assay data and laboratory tests |

| Marimaca Drilling

Apoquindo Minerals 2007 Drilling

Rayrock 2012-2013 Drilling

| |

| Verification of sampling and assaying |

| Marimaca Drilling

Apoquindo Minerals 2007 Drilling

Rayrock 2012-2013 Drilling

| |

| Location of data points |

| Marimaca Drilling

Apoquindo Minerals 2007 Drilling

Rayrock 2012-2013 Drilling

| |

| Data spacing and distribution |

| Marimaca Drilling

Apoquindo Minerals 2007 Drilling

Rayrock 2012-2013 Drilling

| |

| Orientation of data in relation to geological structure |

| Marimaca Drilling

Apoquindo Minerals 2007 Drilling

Rayrock 2012-2013 Drilling

| |

| Sample security |

|

Apoquindo Minerals 2007 Drilling

Rayrock 2012-2013 Drilling

| |

| Audits or reviews |

|

Apoquindo Minerals 2007 Drilling

Rayrock 2012-2013 Drilling

|

Section 2: Reporting of Exploration Results

| Criteria | JORC Code explanation | Commentary | |

| Mineral tenement and land tenure status |

|

| |

| Exploration done by other parties |

| 1. Pampa Medina Concessions

| |

| Geology |

|

| |

| Drill hole Information |

|

| |

| Data aggregation methods |

|

| |

| Relationship between mineralisation widths and intercept lengths |

|

| |

| Diagrams |

|

| |

| Balanced reporting |

|

| |

| Other substantive exploration data |

|

| |

| Further work |

|

|

Images accompanying this announcement are available at:

https://www.globenewswire.com/NewsRoom/AttachmentNg/ebd83cc7-32c9-493b-8f2b-8205d8ddd991

https://www.globenewswire.com/NewsRoom/AttachmentNg/75f8c6e9-748f-45b7-811b-d10081b6ee38

https://www.globenewswire.com/NewsRoom/AttachmentNg/ce351c2c-0e70-4e38-91f5-80a611d22a12

https://www.globenewswire.com/NewsRoom/AttachmentNg/6dc49167-3c63-4adf-a093-db81386be16d

https://www.globenewswire.com/NewsRoom/AttachmentNg/45618dde-70dd-4497-9317-fc020799e5bd

https://www.globenewswire.com/NewsRoom/AttachmentNg/614af86d-9e91-44db-a508-bbe6f395e052